Lear Corporation’s strategic pivot towards extensive automation in its manufacturing processes is a bold maneuver poised to address some of the most pressing challenges in the automotive industry today. As the sector navigates through labor shortages, escalating costs, and the paradigm shift toward electrification and software-defined vehicles, Lear sees automation as the linchpin for maintaining operational efficiency and competitiveness. By embracing automation, Lear aims to not only streamline its manufacturing processes but also set new benchmarks for adaptability and productivity in an ever-evolving industry. The path Lear has embarked upon could offer a viable roadmap for other manufacturers grappling with similar industry challenges.

Labor Shortages and Rising Costs: The Catalyst for Change

Labor shortages have emerged as a critical obstacle for manufacturers across various industries, with the automotive sector feeling a particularly strong pinch. The availability of a skilled workforce has dwindled, creating a widening gap between job vacancies and suitable candidates. This labor scarcity exacerbates the challenge of rising labor costs, making traditional, labor-intensive manufacturing methods increasingly unsustainable. Lear Corporation’s CEO Ray Scott has been vocal about these pressing issues, highlighting the need for innovative approaches to sustain operational efficiencies while curbing escalating expenditures.

In response, Lear has charted a strategic course centered on automation. By investing significantly in automation technologies, the company seeks to mitigate the adverse effects of labor shortages and rising costs. Unlike many of its peers who have scaled back investments amid market uncertainties, Lear has maintained a proactive stance, continuing with acquisitions that amplify its automated manufacturing capabilities. This commitment underscores Lear’s focus on long-term technological advancements and operational resilience. The aggressive investment strategy is not just a short-term fix but a forward-thinking approach aimed at securing the company’s future in an industry fraught with unpredictability.

Automation as the Solution: Lear’s Bold Investments

For Lear, automation represents more than just a solution to labor and cost challenges—it is a necessity for survival and growth in a fiercely competitive landscape. The company’s determined push towards automation is evident through its acquisition of firms like WIP Industrial Automation and ASI Automation, which significantly bolster Lear’s capabilities in AI and automation. These acquisitions are not just about expanding technological assets but are part of a broader vision to integrate these advanced technologies seamlessly into Lear’s manufacturing processes.

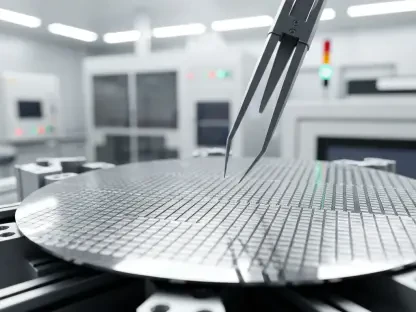

Lear’s approach goes beyond merely purchasing existing automated solutions. The company’s strategy involves the creation and customization of its own capital equipment to meet specific manufacturing needs. This holistic integration allows Lear to exercise greater control, enhance efficiency, and accelerate production timelines. A notable example is the setup of an automated production line for Jeep Wagoneer seats at Lear’s new seating plant in Detroit. Achieving this milestone in just eight months, significantly faster than the industry standard, showcases Lear’s capability to streamline production with better ergonomics and cost-effectiveness. This kind of innovation in manufacturing processes positions Lear as a frontrunner in the industry, capable of responding swiftly and effectively to market demands.

Flexibility in Manufacturing: A Critical Requirement

In the rapidly evolving automotive industry, flexibility in manufacturing operations has become crucial for survival. The swift transition to electric vehicles and the increasing competition from companies like Tesla and new Chinese startups necessitate an unprecedented level of adaptability. Traditional automakers find themselves needing suppliers who can quickly and efficiently adjust to new production requirements, making manufacturing innovation as vital as product innovation. Lear’s investment in automation aligns with this necessity, providing the company with the flexibility to navigate the fast-changing landscape.

Selective capital investments and the customization of automation solutions enable Lear to stay ahead of shifting market demands. These capabilities ensure that Lear remains a dependable partner for traditional OEMs, offering the agility required to keep pace with industry developments. Rapid adaptability, facilitated by targeted investments and innovative manufacturing processes, is setting Lear apart from its competitors. The ability to quickly pivot and modify production lines positions Lear as a supplier of choice in a market where speed and responsiveness are increasingly critical. This strategic advantage allows Lear to thrive amidst the challenges posed by the industry’s evolution towards new technologies and manufacturing paradigms.

Integrated Automation: Enhancing Production Capabilities

Lear’s commitment to integrated automation is evident in its comprehensive strategy aimed at enhancing production capabilities across its facilities. Leveraging advanced automation technologies, Lear seeks to improve operational efficiencies, reduce dependency on manual labor, and streamline production processes. The new Detroit plant serves as a prime example of how controlled automation can significantly boost throughput, improve ergonomics, and reduce overall production costs. This focus on efficiency and flexibility not only addresses labor shortages but also enhances Lear’s ability to meet market demands effectively.

Lear’s aggressive investment in automation is a clear indication of its long-term view and commitment to technological advancements. This uncompromising focus on innovation, rather than short-term financial gains, is crucial for the company’s ongoing success and sustainability. By optimizing production capabilities and integrating cutting-edge technologies, Lear is setting new standards for efficiency and adaptability in automotive manufacturing. This approach reflects a broader trend in the industry where customized and controlled production processes are becoming essential for maintaining competitiveness. Lear’s comprehensive strategy underscores its dedication to driving long-term growth through relentless innovation and strategic investments.

Strategic Acquisitions: Strengthening Automation Capabilities

Lear’s automation strategy is further bolstered by a series of strategic acquisitions aimed at enhancing its technological capabilities. By acquiring companies that specialize in automation and AI, Lear fortifies its ability to integrate advanced technologies into its manufacturing processes effectively. These acquisitions are not merely about expanding Lear’s technological repertoire but are integral to implementing customized automation solutions throughout its operations. This targeted approach ensures that Lear remains at the forefront of innovation in automated manufacturing.

The acquisition of WIP Industrial Automation and ASI Automation, among others, exemplifies Lear’s dedication to strengthening its automation capabilities. By securing access to cutting-edge technologies and specialized expertise, Lear positions itself as a leader in the field of automated manufacturing. These acquisitions are strategic moves designed to enhance Lear’s ability to respond swiftly to industry challenges and evolving market demands. By integrating advanced automation technologies, Lear is better equipped to navigate the complexities of the automotive industry, ensuring its competitiveness and relevance in the face of rapid technological advancements.

The Competitive Edge: Thriving Amidst Industry Challenges

Lear Corporation’s strategic shift towards comprehensive automation in its manufacturing processes is a bold step aimed at tackling some of the automotive industry’s most pressing challenges. As the sector deals with labor shortages, rising costs, and a major transition towards electrification and software-defined vehicles, Lear identifies automation as the key to sustaining operational efficiency and competitiveness. Embracing automation, Lear intends to streamline its manufacturing processes while setting new standards for adaptability and productivity in a constantly evolving industry. This approach is particularly relevant as the industry grapples with increasing complexities and demands for innovation. Lear’s path not only aims to enhance its own production capabilities but also serves as a potential model for other manufacturers facing similar obstacles. By taking this proactive step, Lear positions itself at the forefront of modern manufacturing trends, demonstrating that embracing technological advancements is essential for long-term success in the automotive world.