The realm of robotics has always been divided between two distinct categories: rigid robots and soft robots. Each type has its specific advantages and limitations. Rigid robots, commonly found in industrial settings, boast precision, speed, and considerable torque, allowing them to execute tasks that require substantial force. However, their inherent rigidity poses safety risks when interacting with humans. On the other hand, soft robots, often inspired by the anatomy of biological creatures such as elephant trunks and octopus tentacles, offer remarkable flexibility and maneuverability. This makes them safer for human interaction but, unfortunately, limits their ability to apply significant force or torque.

A New Era for Robotics Design

Combining Strength and Flexibility

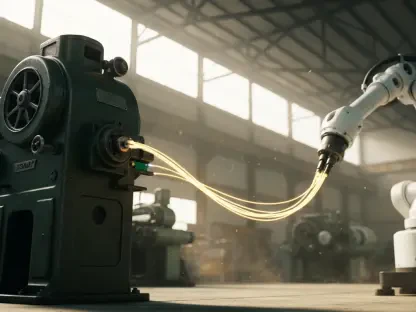

One of the exciting developments in the field is the creation of a hybrid robot that successfully integrates both rigid and soft components. Engineers at Northeastern University, led by Jeffrey Lipton, an assistant professor of mechanical and industrial engineering, have pioneered this innovative advancement. The amalgamation permits the robot to leverage the strength needed for high-torque tasks while maintaining the flexibility required for delicate operations. This breakthrough enables the robot to perform activities that typically challenge traditional robots due to the precision and sensitivity they demand, like screwing in a lightbulb.

Innovative Materials and Design Techniques

To achieve this hybrid functionality, Lipton’s team employed a novel material resembling the function of constant-velocity (CV) joints found in automobiles. Unlike traditional CV joints composed of hard materials, the material developed by Lipton and his colleagues is soft and flexible, yet capable of maintaining the required strength and torque. This approach departs from conventional methods in soft robotics, which often focus on modifying material chemistry. Instead, Lipton’s team utilized a new patterning technique to design the shapes and structures of the materials. This innovation led to the creation of a more versatile robotic arm, capable of adapting and performing various intricate tasks safely and effectively.

Implications for Various Industries

Industrial Automation

The implications of this hybrid robot for industrial automation are profound. Traditional rigid robots excel in tasks requiring high precision and torque but often necessitate safety measures to prevent accidents when humans are nearby. The hybrid robot’s ability to combine the strengths of both rigid and soft robots offers a solution to this limitation by providing a safe and effective way to execute complex tasks. This could revolutionize factory floors by enabling closer collaboration between human workers and robots, ensuring safety without sacrificing efficiency or capability.

Medical Robotics

Another notable potential application for this hybrid robot is in medical robotics. The healthcare industry increasingly relies on robots for surgeries requiring extreme precision, such as minimally invasive procedures. The flexible yet strong nature of this hybrid design could improve the accuracy and safety of such operations. Medical robots that integrate both soft and rigid components can perform delicate tasks without risking damage to human tissues, opening new doors for technological advancements in medicine.

Future Considerations

Research and Development

The ongoing research and development in hybrid robotics are likely to yield more sophisticated and versatile robots. Lipton’s work represents a paradigm shift in robot design, emphasizing the need for robots that can perform a wider range of tasks efficiently and safely. Future research may focus on expanding the capabilities of these hybrid robots, exploring new materials and design techniques to further enhance their adaptability, strength, and safety.

Broader Applications

As the technology of hybrid robotics continues to evolve, its applications will expand beyond industrial automation and medical robotics. Fields such as disaster response, where robots need to operate in complex environments, will benefit from this innovative approach. Similarly, the service industry could see improvements in the interaction between humans and robots, making everyday tasks more efficient while ensuring safety.

The Road Ahead

Technological Integration

The integration of hybrid robots into various sectors will require thoughtful planning and significant investment. Companies and institutions must be prepared to adopt and incorporate these advanced robots into their systems gradually. This involves not only addressing technical challenges but also ensuring that human workers are adequately trained to work alongside these new robotic partners.

Ethical and Societal Impact

The field of robotics is divided into two main categories: rigid robots and soft robots. Each category has distinct strengths and weaknesses. Rigid robots, which are often used in industrial environments, excel in precision, speed, and producing significant torque, allowing them to handle tasks that demand considerable force. Nevertheless, their rigidity can pose safety hazards when used in proximity to humans. Conversely, soft robots, which are inspired by the anatomy of biological organisms like elephant trunks and octopus tentacles, provide exceptional flexibility and maneuverability. These properties make soft robots safer for human interaction but limit their ability to exert substantial force or torque. While rigid robots are optimal for tasks requiring power and precision, soft robots are better suited for applications where gentle handling or safer human interaction is paramount. The divergent properties of these two types of robots reflect the ongoing challenge in robotics: balancing strength with safety and flexibility to meet diverse needs.