The introduction of robotic welding technology is transforming North Lanarkshire’s construction and manufacturing sectors. Initiatives like those at Smart Hub Lanarkshire are spearheading this change, showcasing the technology’s potential to enhance productivity, improve health and safety, and address labor shortages.

The Power of Robotic Welding

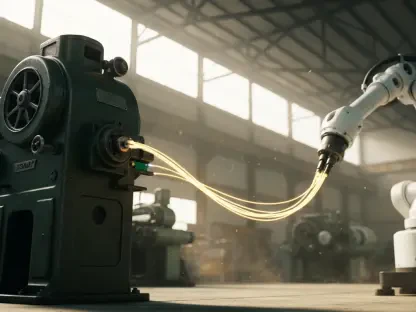

New Era of Construction Technology

The advent of robotic welding technology offers significant benefits to the construction industry. With robotic arms like the Universal Robots UR10E, tasks that once required tedious manual labor can now be automated, ensuring precision and consistency. This transformation leads to higher quality in construction projects, reducing errors and the need for rework, while also allowing for more complex designs to be executed flawlessly.

Smooth Robotics, a Danish firm specializing in robotic welding technologies, has partnered with Smart Hub Lanarkshire to make these advancements accessible to local businesses. Their collaborative efforts provide hands-on experiences that help companies navigate the transition from traditional manual methods to modern, automated processes. By offering practical demonstrations and expert guidance, Smooth Robotics ensures that local enterprises can see firsthand the benefits and applications of robotic welding.

Boosting Productivity and Safety

Automating welding tasks through robotics doesn’t just increase productivity; it also significantly enhances workplace safety. Welding can be hazardous, exposing workers to intense heat, toxic fumes, and the risk of burns or other injuries. Robotic solutions mitigate these risks by taking over the most dangerous aspects of the job, ensuring that human workers remain safe from harm and can focus on tasks that robots cannot easily perform.

The introduction of these technologies is particularly beneficial for older employees, who may find physically demanding tasks increasingly challenging. Robotic welding relieves them from repetitive, strenuous activities, allowing them to focus on supervisory or strategic roles that better suit their experience and knowledge. This shift not only improves overall job satisfaction but also retains valuable institutional knowledge within the workforce.

Hands-On Training at Smart Hub Lanarkshire

Personalized Training Sessions

Smart Hub Lanarkshire’s approach to introducing robotic welding is highly interactive and engaging. They host fully booked events featuring live demonstrations and opportunities for attendees to program robots themselves. These hands-on sessions demystify the technology, making it more approachable and highlighting its practical applications in real-world scenarios that attendees can relate to.

At these events, local businesses can witness the technology’s ease of use firsthand. The smooth integration of Smooth Robotics’ automated programming system with collaborative robots makes the learning curve significantly less steep. This user-friendly approach encourages more companies to adopt these innovative solutions, knowing that their workforce can quickly become proficient in using the technology with minimal disruption to their operations.

Addressing Job Displacement Concerns

One of the main obstacles to adopting robotic welding is the fear of job displacement among workers. To counter this concern, Smooth Robotics’ Sales Manager Kenneth Pedersen emphasizes that the technology should be viewed as an aid rather than a replacement for workers. This perspective is crucial for gaining the trust of employees, particularly older ones who might be more skeptical of technological advancements and concerned about their job security.

Ryan Sheridan, the operational lead at Smart Hub Lanarkshire, reinforces this message by stressing the accessibility and user-friendly nature of these robotic systems. By providing concrete examples and hands-on experiences, Smart Hub helps businesses realize the feasibility of integrating such technology into their operations without fearing significant workforce reductions. This approach ensures that the focus remains on enhancing job roles rather than eliminating them.

Educational Initiatives and Long-Term Goals

Training the Workforce of Tomorrow

North Lanarkshire College is an integral part of this initiative, playing a crucial role in preparing the next generation of workers for the future of manufacturing. By incorporating robotics training into their curriculum, the college ensures that students gain hands-on experience with cobots, making them well-versed in the latest technological advancements and highly competitive in the job market.

Plans to develop recognized qualifications in operating collaborative robots further ensure that these skills are formally acknowledged, significantly boosting students’ career prospects. The college’s proactive approach aligns perfectly with industry needs, making students valuable assets to prospective employers who are increasingly looking for technologically adept employees capable of navigating modern manufacturing environments.

Inspiring Future Generations

The outreach efforts extend to local schools, where children are introduced to advanced manufacturing technologies at an early age. This early exposure aims to change outdated perceptions of the industry and inspire young minds to consider careers in modern engineering and manufacturing. These initiatives are critical for ensuring a steady stream of skilled workers for the future, addressing both immediate and long-term workforce needs.

Through interactive sessions with tablet-controlled robotic systems, students quickly adapt, demonstrating the user-friendly nature of these technologies. This early engagement is essential in transforming the industry’s image and encouraging the next generation to see manufacturing as a high-tech, appealing field. By engaging with advanced technologies from a young age, these children are more likely to pursue careers in engineering and manufacturing, ensuring the industry’s continued growth and innovation.

Local Industry Resurgence

Reducing Reliance on Imports

The broader objective of introducing robotic welding technology is to rejuvenate Scotland’s engineering and manufacturing prowess. By equipping local businesses with cutting-edge technologies, Smart Hub Lanarkshire aims to reduce dependency on imports, fostering a stronger local economy and stimulating job creation. This self-sufficiency not only boosts the local industry but also lays a solid foundation for sustained economic growth and development.

The initiative’s success is evident in the high turnout at events and the overwhelmingly positive feedback from participants. Businesses recognize the potential for increased efficiency and are motivated to integrate robotic solutions into their operations. This growing acceptance and enthusiasm for robotic welding technology mark a significant step forward in modernizing North Lanarkshire’s construction and manufacturing sectors.

A Global Movement Towards Technological Integration

The integration of robotic welding technology is revolutionizing the construction and manufacturing industries in North Lanarkshire. Key initiatives, particularly those at Smart Hub Lanarkshire, are leading this technological transformation. These advancements are not just about adopting new technology; they signal a significant shift in how these industries operate. By incorporating robotic welding, companies can greatly enhance productivity and efficiency, which is crucial in a highly competitive market.

Beyond productivity gains, robotic welding technology dramatically improves health and safety standards. Traditional welding is physically demanding and poses various health risks, including exposure to hazardous fumes and the potential for injuries. Robotic systems mitigate these risks by taking over the more dangerous tasks, thereby creating a safer work environment for human workers.

Additionally, this technology is a strategic response to ongoing labor shortages. Skilled welders are in short supply, and robotic systems offer a viable solution by filling in these gaps. This not only helps maintain steady production rates but also allows businesses to thrive despite workforce challenges.