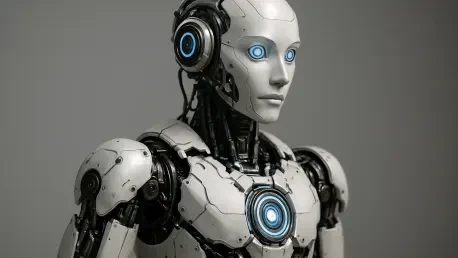

Imagine a world where a helmet molds perfectly to your head, a hospital bedsheet adjusts to support a patient’s needs, or a robot shifts its form to navigate complex terrains—all without human intervention. This isn’t science fiction; it’s the frontier of robotics, driven by artificial intelligence (AI) that automates the design of shape-changing robots. Specifically, metatruss robots, with their intricate systems of beams and joints, are leading this transformation, inspired by the adaptability of natural organisms like octopuses. This review dives into a groundbreaking AI framework that optimizes these complex designs, addressing the monumental challenges of control and functionality while paving the way for innovative applications across industries.

Core Features of AI in Robot Design

The heart of this technological leap lies in the convergence of AI and robotics, particularly through the development of metatruss structures capable of volumetric transformations. These robots are built from hundreds of interconnected beams and joints that can twist and rotate, enabling dramatic shape changes. However, as functionality increases with additional actuating components, so does the complexity of control, often requiring an impractical number of control units. The AI framework tackles this by automating the design process, reducing human effort and enhancing precision in achieving desired shapes and movements.

A standout feature of this technology is its use of genetic algorithms to navigate the vast design space. These algorithms systematically test countless configurations to find the optimal balance between performance and control simplicity. By determining the minimal number of control units needed for tasks like morphing or locomotion, the framework ensures efficiency without sacrificing capability, a critical advancement for scalable robotic systems.

Beyond optimization, the integration of bio-inspired principles sets this technology apart. Drawing from concepts like muscle synergy in living organisms, the AI coordinates groups of actuators to function as a unified system rather than individual components. This approach mirrors how muscles work together in nature, significantly cutting down on control complexity while maintaining adaptability, thus making the robots more practical for real-world deployment.

Performance and Practical Applications

When it comes to performance, the AI-driven framework has demonstrated remarkable results through various prototypes. A quadruped robot showcases agile movement across uneven surfaces, while a shape-shifting helmet adjusts to different head shapes with minimal control inputs. Additionally, a lobster-inspired walking robot and a tentacle-like actuator highlight the versatility of metatruss designs in mimicking natural motions, proving the framework’s ability to handle diverse functional demands.

The real-world potential of these robots extends far beyond experimental models. Envision wearable devices that adapt to user movements, hospital bedsheets that morph to assist in patient care, or furniture that reconfigures based on spatial needs. These applications illustrate how shape-changing robots could integrate seamlessly into everyday environments, bringing robotic functionality to human-centric spaces with unprecedented ease.

Testing has also revealed a key insight: there exists an optimal number of control channels for each design, beyond which performance gains diminish. The AI’s ability to statistically identify this balance ensures that robots are neither over-engineered nor underperforming, a feat that manual design struggles to achieve. This precision in performance optimization marks a significant step forward in robotics engineering.

Challenges in Implementation

Despite its promise, the adoption of AI-driven metatruss robots faces notable hurdles. The computational demands of running genetic algorithms for design optimization require substantial resources, potentially limiting accessibility for smaller research teams or companies. Moreover, the intricate nature of truss systems poses manufacturing challenges, as producing hundreds of precise beams and joints at scale remains costly and technically demanding.

Regulatory and technical barriers also loom on the horizon. Ensuring safety and reliability in shape-changing robots, especially for applications in healthcare or personal use, will require stringent standards and testing protocols. Current efforts in research aim to address these issues by refining AI algorithms for efficiency and exploring cost-effective fabrication methods, though widespread implementation remains a complex goal.

Looking Ahead to Future Innovations

As this technology evolves, the future holds exciting possibilities for morphing robotics. The integration of generative AI and large language models could lead to fully automated, personalized robot designs tailored to specific user needs or environments. Imagine a scenario where a simple voice command prompts the creation of a custom robotic solution, designed and optimized in real-time without human input.

Over the next few years, from 2025 to 2027, advancements in computational power and AI sophistication are expected to further reduce design timelines and costs. This could democratize access to shape-changing robots, allowing industries like healthcare, consumer goods, and logistics to adopt adaptive systems at an accelerated pace. The potential for these robots to become integral to daily life grows stronger with each innovation.

The long-term vision includes transforming mundane objects into dynamic, robotic entities. Concepts such as hospital bedsheets with embedded truss units to assist in patient mobility or furniture that adapts to spatial constraints could redefine comfort and functionality. Continued research and collaboration across disciplines will be crucial to realizing these ambitious goals.

Final Thoughts on a Transformative Technology

Reflecting on this review, the exploration of AI-driven design for shape-changing robots reveals a field brimming with potential, marked by significant strides in optimization and bio-inspired innovation. The prototypes tested showcased impressive adaptability and efficiency, setting a high benchmark for what robotic systems could achieve. Challenges in computation and manufacturing were acknowledged as critical areas that demand attention.

Moving forward, the focus shifts to actionable steps, such as investing in scalable AI tools to lower resource demands and fostering partnerships for advanced manufacturing techniques. Encouraging interdisciplinary research to refine bio-inspired approaches emerges as a vital strategy to overcome technical barriers. Ultimately, nurturing global dialogue on regulatory frameworks becomes essential to ensure safe integration of this technology into everyday applications, promising a future where adaptive robots enhance lives in unimaginable ways.