In the high-stakes world of global shipbuilding, where immense steel structures are forged into titans of the sea, the industry is grappling with an escalating labor crisis that threatens to capsize its future growth. Korean shipbuilder HD Hyundai Samho is charting a bold new course, actively developing plans to integrate humanoid robots into its shipyard operations as a strategic response to these significant labor shortages and to fortify its competitive position against China, the world’s shipbuilding leader. The company is currently in the critical phase of analyzing the return on investment (ROI) to pinpoint the most effective and economically viable applications for these advanced machines. This initiative is not merely an experiment but a calculated move to redefine productivity and efficiency in an industry steeped in tradition yet facing unprecedented modern challenges. The potential integration of bipedal, autonomous workers represents a pivotal moment, potentially heralding a new era of automated manufacturing on a scale previously confined to science fiction.

A Strategic Leap into Automation

The groundwork for this technological transformation is already being laid following a successful demonstration where humanoid robots adeptly performed complex tasks, including precision welding and heavy material handling. To bring this vision to life, HD Hyundai Samho is leveraging a powerful partnership, collaborating with its own internal robotics division alongside industry pioneers Neura Robotics and LG CNS. This synergy is crucial for advancing a project of this magnitude. The company has outlined a phased rollout targeted for 2027, which will begin by assigning the robots to lower-level, repetitive tasks to prove their reliability and effectiveness in a real-world shipyard environment. As the technology matures and the robots learn, they will progressively be assigned more complex and nuanced functions. In parallel, the shipbuilder is committed to preparing its human workforce for this evolution through intensive AI training programs designed to cultivate the skills necessary to work alongside and manage their new robotic colleagues, ensuring a smooth and productive transition into a hybrid human-robot workplace.

Overcoming Hurdles and Building on Success

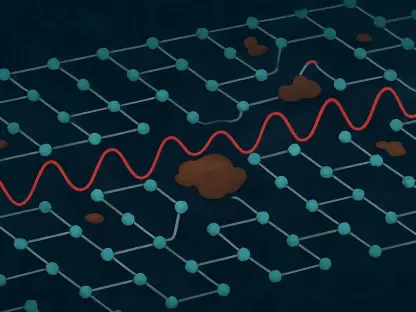

The primary impetus for this ambitious technological pivot was South Korea’s pressing demographic challenges, including a rapidly aging population and a shrinking domestic labor pool, which had led to a significant and often challenging reliance on foreign workers to fill critical gaps. Humanoid robots were identified as a critical solution to this persistent workforce deficit, offering a path to sustained productivity and potential expansion into other labor-scarce markets, such as the United States. While these robots offered the distinct advantage of operating in environments designed for humans without requiring extensive infrastructure changes, they faced considerable technical hurdles. Navigating the uneven surfaces, cluttered pathways, and harsh, corrosive conditions of a shipyard presented a far greater challenge than a controlled factory floor. However, this initiative did not emerge from a vacuum; the company had already found measurable success with other robotic solutions, including the deployment of semi-autonomous welding co-bots and agile, four-legged mobile robots on its panel assembly lines, which provided a solid foundation of experience and confidence for this next evolutionary step in automation.