In the realm of robotics, where precision and complexity often reign supreme, a groundbreaking shift is emerging with the development of robots that operate without a traditional electronic brain, marking a significant departure from conventional designs. A research team from the University of Oxford has pioneered a class of “brain-free” robots powered entirely by air pressure. These machines encode behavior and decision-making directly into their physical structures, eliminating the need for intricate electronic control systems or programming.

This innovation tackles a persistent challenge in soft robotics: achieving adaptability and autonomous behavior in unpredictable environments. Unlike rigid robots, soft robots are designed for flexibility, making them ideal for tasks like navigating uneven terrain or interacting with fragile objects. However, their reliance on external control systems often limits their responsiveness. The air-powered approach offers a promising solution by embedding intelligence within the robot’s form, paving the way for more intuitive and resilient machines.

The concept of brain-free robotics introduces a paradigm where physical design dictates function, drawing inspiration from natural systems that operate without centralized control. This method not only simplifies the construction of robots but also enhances their ability to adapt to dynamic settings. As this field evolves, it could redefine how robotic autonomy is perceived and implemented across various applications.

The Context and Importance of Air-Powered Soft Robots

Traditional robotics has long depended on electronic components, sophisticated motors, and complex algorithms to execute tasks, often resulting in bulky and energy-intensive systems. These designs, while effective in controlled settings, struggle in scenarios requiring flexibility and quick adaptation. Soft robotics, by contrast, prioritizes pliability and gentleness, making it suitable for delicate operations or challenging terrains where rigid structures falter.

Air-powered soft robots represent a significant leap forward by stripping away the need for electronic dependencies, focusing instead on mechanical simplicity driven by fluidic pressure. Their relevance extends beyond mere design innovation; they promise enhanced energy efficiency and ease of deployment in extreme or resource-scarce environments such as disaster zones. In such areas, where power sources may be unreliable, a robot that functions without electricity could prove invaluable for rescue or exploration missions.

Moreover, this advancement aligns with broader goals in robotics to create systems that are both sustainable and accessible. By reducing reliance on computational hardware, these air-driven robots could lower production costs and environmental impact, broadening their potential use in diverse fields. This shift toward simpler yet effective technology underscores a growing recognition of the need for robust solutions in an increasingly complex world.

Research Methodology, Findings, and Implications

Methodology

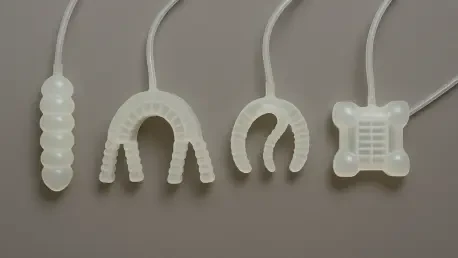

The research focused on developing modular fluidic units that harness air pressure to function as actuators, sensors, and switches within a single component. These units, roughly a few centimeters in size, were designed to be versatile, allowing assembly into various robotic configurations without altering the core hardware. This modularity mirrors the concept of building blocks, enabling flexibility in design and application.

Experiments involved constructing tabletop robots, such as shaker and crawler models, approximately the size of a shoebox. A constant supply of air pressure was applied to drive movement, with the units autonomously combining their multifunctional roles to produce rhythmic motions. The setups were meticulously tested to observe how physical interactions influenced behavior, particularly in terms of coordination and response to environmental stimuli.

To analyze the synchronization of robotic movements, the Kuramoto model—a mathematical framework typically used to study oscillator networks—was employed. This model helped elucidate how physical coupling, such as shared forces through contact or friction, led to coordinated actions among multiple units. The approach provided a deeper understanding of how decentralized systems could achieve harmony without external directives.

Findings

The study revealed that the fluidic units successfully performed multiple roles, enabling complex behaviors like hopping, shaking, and crawling without any electronic intervention. When connected within a single robot, these units demonstrated remarkable synchronization, with movements aligning naturally through physical interactions rather than programmed instructions. This emergent coordination was driven by environmental feedback, such as ground reaction forces, showcasing a novel form of mechanical intelligence.

Specific behaviors observed included a shaker robot sorting beads into containers via a tilting platform and a crawler robot detecting table edges to avoid falls. These actions, achieved purely through structural design and air pressure, highlighted the potential for autonomous decision-making embedded in the robot’s form. Such capabilities suggest that even basic tasks can be executed with high efficiency when control is decentralized.

Additionally, the research underscored the scalability of the fluidic design, as the principles of operation remained consistent across different configurations. The synchronization, explained through the Kuramoto model, mirrored patterns seen in natural systems, reinforcing the idea that physical coupling can replicate organic coordination. These results mark a pivotal advancement in demonstrating how simplicity in design can yield sophisticated outcomes.

Implications

This breakthrough addresses critical barriers in soft robotics by mimicking natural systems where decentralized coordination is inherent, such as in the synchronized flashing of fireflies or the movement of animal limbs. By embedding intelligence into the robot’s structure, the technology bypasses the need for complex computational systems, potentially leading to faster and more responsive machines. This approach could redefine how adaptability is achieved in robotic applications.

Practical applications are vast, ranging from deploying these robots in dynamic environments like disaster response to using them for delicate tasks in medical or industrial settings. Their energy efficiency and lack of electronic components make them particularly suited for scenarios where power is limited or conditions are harsh. The simplicity of the design also suggests lower maintenance needs, enhancing their usability in real-world contexts.

Theoretically, this research challenges conventional robotic design by prioritizing mechanical solutions over computational ones, offering a fresh perspective on embodied intelligence. Societally, it promises improved systems for challenging environments, potentially transforming how assistance is provided in crises or remote areas. This shift toward structural autonomy could inspire a rethinking of robotic roles across multiple disciplines.

Reflection and Future Directions

Reflection

The innovative use of air pressure as a sole power source in robotics represents a bold departure from traditional methods, emphasizing the potential of mechanical systems to achieve complex behaviors. Crafting synchronized movements without external control posed significant challenges, requiring meticulous design of fluidic units to ensure seamless interaction. The research team navigated these hurdles by focusing on physical coupling as a driver of coordination, a strategy that proved both effective and insightful.

Scaling the current tabletop prototypes to larger or more intricate forms emerged as a notable limitation during the study. While the principles are scale-independent, practical constraints in material durability and air supply management were acknowledged as areas needing refinement. Exploring additional robotic configurations or diverse applications could have further enriched the findings, providing a broader view of the technology’s versatility.

Drawing inspiration from natural emergent behaviors, such as those observed in collective animal actions, added a unique dimension to the project. This interdisciplinary approach, blending insights from biology and engineering, highlighted the value of looking beyond conventional frameworks. Such cross-pollination of ideas could continue to yield novel solutions in the evolving landscape of robotics.

Future Directions

Looking ahead, scaling the fluidic units for both larger and smaller robots presents a compelling avenue for research, potentially expanding their applicability across different domains. Testing these systems in real-world, untethered scenarios would provide critical data on their performance outside controlled environments. Such experiments could validate their effectiveness in practical settings, from urban search missions to rural explorations.

Another promising direction involves developing energy-efficient locomotion tailored for disaster response or remote exploration, where simplicity and adaptability are paramount. Enhancing the robots’ ability to operate independently in harsh conditions could address pressing needs in emergency situations. Research into lightweight, portable air supply mechanisms might further support this goal, ensuring operational feasibility in diverse contexts.

Unanswered questions, such as the long-term durability of air-powered systems under continuous use, warrant deeper investigation. Additionally, integrating more complex decision-making capabilities into physical structures without sacrificing simplicity remains a challenge. Addressing these gaps could unlock new potentials, pushing the boundaries of what brain-free robotics can achieve in the coming years, from 2025 onward.

Redefining Robotics: A Vision for the Future

The advent of air-powered, brain-free robots stands as a transformative milestone in soft robotics, emphasizing modularity, synchronization, and embodied intelligence as core principles. These machines, driven by fluidic units and physical interactions, demonstrate that complex behaviors can emerge from simple designs, mirroring the efficiency of natural systems. This research underscores a shift toward creating adaptive, efficient technologies that prioritize structural ingenuity over computational load.

Reflecting on the journey, the development of robots that operate without electronic brains challenged long-held assumptions about control and autonomy. The success in achieving synchronized movements through air pressure alone opened new pathways for innovation. It highlighted the untapped potential of mechanical solutions in addressing modern robotic challenges.

Moving forward, actionable steps include investing in material advancements to enhance the durability of fluidic units and collaborating across disciplines to integrate bio-inspired designs. Partnerships with industries focused on disaster response could accelerate the deployment of these robots in critical missions by 2027. Ultimately, this breakthrough serves as a catalyst for reimagining robotic design, inspiring a future where physical intelligence drives progress in diverse fields with unprecedented impact.