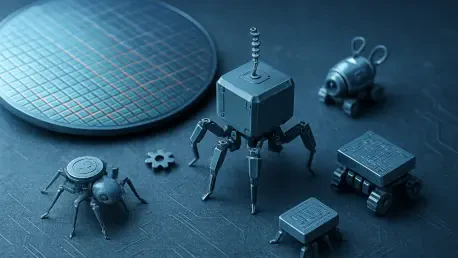

What if machines so small they could dance on the head of a pin held the power to revolutionize surgery, manufacturing, and wearable tech? In labs at Carnegie Mellon University, researchers are turning this once-fanciful idea into reality, crafting robots tinier than a grain of salt with precision that boggles the mind. These microscale marvels, born from cutting-edge 3D nanofabrication techniques, are not just a scientific curiosity—they’re poised to redefine how industries tackle the smallest, most delicate tasks. This story dives into the astonishing world of microrobotics, where the impossible is becoming possible.

Why Microscale Robots Are a Game-Changer

The significance of these tiny robots lies in their potential to solve problems that larger machines and human hands simply cannot. In healthcare, they could navigate inside the body for minimally invasive procedures; in manufacturing, they could assemble microscopic components with unmatched accuracy. As technology races toward greater precision and efficiency, the ability to build and deploy robots at such a minuscule scale addresses urgent needs across multiple fields. This isn’t just about shrinking machines—it’s about expanding what’s achievable in spaces too small for traditional tools.

The stakes are high, and the implications are vast. With industries clamoring for solutions that blend speed, accuracy, and compactness, microscale robots offer a glimpse into a future where limitations of size no longer dictate capability. Understanding how these innovations come to life through advanced fabrication methods reveals not only a technological breakthrough but also a shift in how society approaches complex challenges.

Breaking Down the Science of 3D Nanofabrication

At the heart of this revolution is 3D nanofabrication, a process that constructs intricate structures at scales invisible to the naked eye. One standout technique, two-photon polymerization, uses a focused laser to solidify photosensitive materials with pinpoint accuracy, creating detailed 3D shapes as small as 0.7 mm. A thin metal coating then adds electrical functionality, transforming these structures into working robotic mechanisms without the need for tedious manual assembly.

This method marks a stark departure from past struggles in microrobotics, where labor-intensive folding of components slowed progress since the early days of micro-electro-mechanical systems. By automating the creation of complex designs, researchers can now produce robots like the microDelta—a miniaturized version of industrial Delta robots used for tasks such as picking and sorting. These tiny versions achieve sub-micrometer precision and operate at frequencies exceeding 1 kHz, showcasing capabilities that were once thought unattainable.

The speed of innovation is equally impressive. Traditional approaches often took weeks or months for a single design cycle, but with this 3D printing process, eight iterations of the microDelta were completed in record time. This rapid prototyping paves the way for continuous refinement, ensuring that each version pushes the boundaries of what these miniature machines can do.

Voices Shaping the Future of Microrobotics

Experts at the forefront of this field are buzzing with excitement over what’s been achieved and what lies ahead. Professor Sarah Bergbreiter from Carnegie Mellon University, who spearheaded this research, highlights the accessibility of the technology: “This streamlined fabrication process allows future innovators to build on current designs, enhancing speed, precision, and even adding autonomous sensing capabilities.” Her words point to a collaborative future where students and researchers can iterate quickly on existing work.

Other faculty members, including Zeynep Temel and Oliver Kroemer from the Robotics Institute, are already exploring how arrays of these microDelta robots could function at varying scales. Their interest signals a growing momentum, with potential applications spanning far beyond initial experiments. Performance data, such as the microDelta’s ability to launch objects weighing 7.4% of its own mass, adds concrete evidence to the enthusiasm, proving that these robots are not just small but also remarkably powerful for their size.

Real-World Impact of Tiny Robots

The practical uses of these microscale machines are as diverse as they are transformative. In micromanipulation and microassembly, microDeltas could handle tasks requiring extreme delicacy, such as constructing tiny electronic components. Their precision makes them ideal for industries where even the slightest error can be costly, offering a level of control that surpasses human capability.

In the medical field, their small footprint opens doors to minimally invasive surgeries, allowing procedures in confined spaces with reduced risk and faster recovery times for patients. Beyond that, wearable haptic devices could integrate arrays of these robots to deliver detailed tactile feedback, enhancing virtual reality systems or aiding in physical rehabilitation. Each application underscores how scaling down robotics can lead to outsized impacts in everyday life.

Looking further, the concept of densely packed microDelta arrays hints at even more complex systems. Such configurations could tackle intricate industrial tasks or create sophisticated feedback mechanisms, blending multiple tiny robots into a cohesive unit. Tailoring designs for specific needs—whether by boosting power-to-weight ratios or embedding advanced sensors—ensures these innovations meet real-world demands while continuing to evolve.

Reflecting on a Microscopic Revolution

Looking back, the journey to create robots smaller than a grain of salt stands as a testament to human ingenuity and perseverance. Overcoming decades of fabrication challenges, researchers crafted microDeltas that validated long-standing theories about the benefits of miniaturization. Their achievements in precision, speed, and rapid design iteration marked a turning point for industries hungry for compact, efficient solutions.

As this field progresses, the next steps involve scaling up collaboration and investment to refine these technologies further. Exploring how to integrate closed-loop sensing for autonomous operation emerges as a key priority, alongside expanding applications in healthcare and beyond. The path forward demands a collective effort to turn these microscopic marvels into tools that can reshape daily life, proving that even the smallest innovations can carry the mightiest potential.