The modern smart factory is often envisioned as a futuristic landscape of autonomous robots and predictive artificial intelligence, but the true bedrock of this industrial revolution is built upon a far less visible, yet infinitely more critical, framework of universally accepted standards. These are not merely restrictive technical guidelines but the collaborative DNA that enables disparate technologies to communicate, ensures operational safety, and drives efficiency on a global scale. Without this common language, the symphony of interconnected systems would devolve into a cacophony of isolated, incompatible components. Understanding the development, application, and evolution of these standards is essential to grasping how today’s manufacturing marvels are constructed and how the factories of tomorrow will be engineered for even greater resilience and innovation. This foundational infrastructure is what transforms the theoretical promise of Industry 4.0 into a tangible, operational reality.

The Collaborative Blueprint for Global Innovation

The primary motivation behind the creation of automation standards has always been the methodical elimination of inconsistencies, variations, and exceptions that impede industrial progress. By establishing a comprehensive and consistent framework, engineers and technicians around the world can adopt a unified approach to complex operational scenarios, thereby significantly reducing ambiguity and the costly, time-consuming process of re-engineering solutions for common problems. This collaborative process, which spans multiple sectors, is exemplified by pivotal industry standards such as ISA 88. Designed specifically for batch control, ISA 88 provides an essential framework for ensuring procedural consistency in industries where precise, repeatable processes are paramount, including pharmaceuticals, food and beverage, and specialized segments of automotive manufacturing. By defining a common terminology and structure for batch processing, this standard allows for the development of modular, reusable control strategies that streamline production and enhance product quality across diverse applications, serving as a testament to how targeted standards directly address and resolve persistent industry-wide challenges.

The challenge of standardization is magnified by the exceptionally long operational lifespans of industrial plants and the vast diversity of global manufacturing practices. Standards like ISA 112 directly confront this reality by focusing on the life cycle assessment of SCADA systems, providing a standardized methodology for integrating legacy equipment—often decades old and verging on obsolescence—with modern technologies. This is crucial for facilities that may operate for 60 to 80 years or more. A similar challenge exists in harmonizing physical components, particularly electrical cabling and sensors. Different global regions adhere to varied manufacturing standards, resulting in multiple, often conflicting, wiring approaches. This divergence turns troubleshooting into a complex, protracted process requiring extensive communication between on-site technicians and remote engineers. The ultimate goal of this harmonization effort is to develop a unified set of practices for ratification by global bodies like the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC), creating a stable, predictable platform for global innovation and empowering engineers to implement more consistent and easily maintainable systems worldwide.

Navigating Modern Hurdles in Automotive Automation

The automotive industry is currently navigating a period of intense transformation, driven by the complex shift to multi-powertrain production lines that accommodate BEV, hybrid, and ICE vehicles simultaneously, all while contending with persistent labor and skills shortages. These pressures have magnified the importance of flexible and efficient automation, yet significant hurdles remain. One of the most prominent is the fragmentation of Human-Machine Interfaces (HMIs). The market is saturated with platforms from major manufacturers like Allen Bradley, Beckhoff, and Siemens, each possessing a unique design philosophy. This diversity leads to a profound lack of standardization in HMI templates, as different integration engineers prioritize different design approaches. For operators on the factory floor, this creates a disjointed and cognitively demanding experience, forcing them to navigate steep learning curves and adapt to different system logics and interface layouts at various workstations. This inconsistency not only increases the potential for human error but also acts as a direct brake on operational efficiency and workforce flexibility.

Beyond the operator interface, controls engineers tasked with system revamps face a critical decision regarding communication technology, often revealing a deep-seated tension between innovation and institutional inertia. The market offers a wide spectrum of options, from modern, high-speed protocols like Ethernet and EtherCAT to proven legacy systems such as CAN and Modbus. There is a prevalent conservative tendency among professionals to opt for familiar, older technologies, even when more advanced and modular options are available that could offer superior performance and scalability. This reluctance often stems from a deep-seated resistance to disrupting existing, functional systems and an organizational focus on immediate, short-term cost-cutting over long-term operational excellence. A more strategic, forward-looking perspective is essential. This requires a holistic view of technological integration that carefully weighs the nuanced trade-offs between short-term savings and long-term gains, demanding not just deep technical expertise but also a strategic vision capable of anticipating future manufacturing requirements and technological trends.

Integrating Intelligence with AI and Advanced Robotics

Artificial Intelligence is poised to be a transformative force in industrial automation, evolving into a sophisticated companion for engineers that is capable of bridging critical skills gaps and optimizing complex processes. One of its most promising applications lies in AI-powered programming assistance. Such intelligent systems could translate between complex programming languages, effectively creating a communication bridge between software engineers and controls engineers, thereby democratizing access to advanced automation. In HMI development, AI holds the potential to revolutionize the creation of templates and streamline system integration, showing particular promise in navigating the intricate configurations of cybersecurity by offering intelligent suggestions and automating what is traditionally a complex, manual process. Perhaps most compelling is AI’s potential in predictive equipment analysis. By processing and analyzing extensive data from PLC operations, AI systems can help organizations make highly informed decisions about equipment necessity, identifying redundant systems and optimizing resource allocation with a remarkable level of precision.

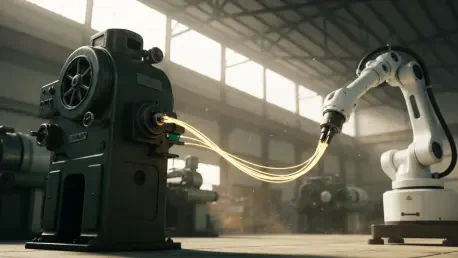

This drive toward intelligent automation is powerfully complemented by recent technological advancements in industrial robotics, which have dramatically enhanced factory adaptability and flexibility. Modern vision systems now enable robots to recognize and differentiate between similar products with far greater accuracy, automatically adjusting vision offsets to continue operations with minimal human intervention. Lightweight robots have developed sophisticated path-learning capabilities, which are especially valuable in high-mix, low-volume manufacturing scenarios that demand more dynamic and flexible processes. Another significant leap forward is the ability for robots to change end-of-arm tools dynamically, seamlessly switching between grippers, welders, or other implements based on specific production recipes. This capability unlocks a level of manufacturing agility that was previously unattainable, allowing a single robotic cell to perform a variety of tasks and adapt to changing product lines with unprecedented speed and efficiency.

A Foundation of Human-Centric and Secure Design

The successful transition to a fully integrated smart factory requires a delicate balance between ambitious innovation and pragmatic resource management. A nuanced approach is most effective, suggesting that when a system’s mechanical design is fundamentally sound and predictable, organizations should prioritize digitization and software optimization over costly and disruptive wholesale mechanical replacements. While software-based solutions offer a more cost-effective and flexible path to modernization, blind trust in AI-generated solutions is unwise; a robust human review process remains critical to ensure technological innovations align perfectly with real-world operational requirements and safety protocols. This focus on human oversight is part of a broader, people-centric approach to automation. Drawing from standards like ISA 101, technological innovation must prioritize user experience and operational intuition, which translates to HMI designs founded on clarity and simplicity. A neutral color palette serves as the default, with bright, attention-grabbing colors reserved exclusively for critical faults, and systems are made more accessible through visual guides that reduce reliance on dense documentation and lower the cognitive load on operators.

This human-centric philosophy was ultimately protected by a sophisticated, multi-layered cybersecurity strategy that became a non-negotiable prerequisite for smart factory success. A system architecture was established to carefully manage information flow, with each level designed to share only the minimum necessary information to prevent compromises from cascading across the network. This design was fortified with advanced gateways, robust authentication protocols, and carefully controlled read/write access to critical system parameters. It was this holistic approach—skillfully balancing cutting-edge AI and robotics with strategic system design and a profound understanding of human operational needs—that ultimately defined the future of manufacturing. Sustained success belonged to those who integrated advanced technologies upon a foundation of comprehensive standards while maintaining an unwavering focus on human capabilities, robust security, and long-term operational efficiency.