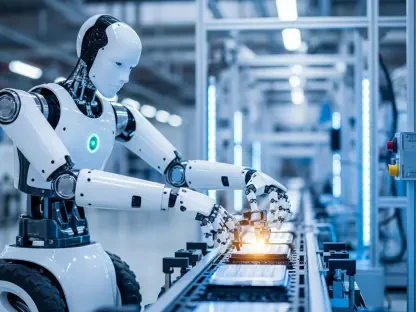

The world of industrial automation is undergoing a significant transformation, driven by the integration of cutting-edge technologies such as Deep Reinforcement Learning (DRL). On the brink of sweeping change, industries are immersed in a digital revolution where traditional process control systems face the challenge of keeping up with contemporary demands for efficiency, scalability, and sustainability. Deep Reinforcement Learning, coupled with innovative online process analyzers, offers a new frontier in optimizing complex industrial processes. As industries contend with fluctuating raw material prices, heightened market competition, and the imperative for reduced environmental impact, the role of DRL emerges as pivotal in addressing these multifaceted challenges. The fusion of autonomous learning algorithms with real-time data analytics unlocks unparalleled levels of operational efficiency and sets a new benchmark for sustainable manufacturing practices.

Harnessing Deep Reinforcement Learning for Enhanced Process Optimization

At the heart of this technological shift lies the proposition that DRL, when integrated with online process analyzers, provides a formidable alternative to legacy methods of process control. Unlike conventional strategies, which often rely on static models, DRL imbues industrial systems with the capacity for continuous learning and adaptation. This approach is particularly invaluable in environments characterized by non-linear complexities and variable load conditions. By utilizing Machine Learning (ML) embedded within digital twins—digital replicas of physical processes—industries are empowered to simulate, learn, and develop optimal control strategies without exposing actual assets to risk. Yet, realizing the full potential of this approach mandates robust system design, a resilient data infrastructure, and an unceasing cycle of model refinement and validation.

Deep Learning models, especially DRL, bring the advantage of using historical data to discern intricate dependencies among various process parameters. However, this reliance on historical data does have its constraints. ML models are trained within specific statistical domains, which poses limitations when it comes to extrapolating beyond these trained domains and navigating highly non-linear response surfaces. In the real world, industrial processes often present complex, non-linear dynamics, with multiple local minima that demand computationally intensive approaches to find global optima, particularly in real-time applications. This necessitates a different approach to overcome such constraints and ensure effective deployment in dynamic industrial settings.

Deep Reinforcement Learning: A Paradigm Shift in Control Strategies

In addressing these challenges, Deep Reinforcement Learning emerges as a robust solution, taking inspiration from biological learning processes. DRL agents are designed to interact with their environment autonomously, drawing feedback from actions to gradually refine their decision-making policies and maximize cumulative rewards in the process. The chief objective of a DRL agent is to map each state of a process to its optimal control actions. Training commonly occurs within a simulation environment using digital twins; this method helps avert risks that might otherwise affect the actual world. This simulation-based approach enables extensive exploration and development of decision policies without compromising safety or stability in real-world operations.

Simulation environments provide a controlled setting for safe learning, although limited by the scope of data they encapsulate. Digital twins, functioning as high-fidelity simulants, facilitate the DRL process, providing a virtual ground for the agents. To counterbalance their inherent limitations, industries adopt a closed-loop strategy encompassing DRL control, data-capturing online analyzers, and a dynamic process for continuous model updating. As DRL controllers explore unknown process states, online analyzers acquire precise data about the emerging system behaviors, feeding it back into the models. This enhances the retraining and updating of digital twins, bolstering prediction accuracy as agents traverse newly ventured operating domains.

DRL Versus Traditional Control Methods

The efficacy of DRL over traditional non-linear Model Predictive Control (NMPC) becomes especially pronounced when considering DRL’s pre-training advantage. Whereas NMPC often incurs expensive online optimization costs, DRL leverages its exploration capabilities during simulation to craft robust policies conducive to complex systems. This minimizes the propensity for getting trapped in local optima, rendering DRL an appealing candidate for scalable applications and dynamic supply chains. Furthermore, the adaptive methodologies intrinsic to DRL make it ideal for managing the unpredictable arena of modern industries where demand volatility and fluctuating conditions necessitate flexible and responsive control systems.

DRL’s potential lies not only in optimization capabilities but also in reducing the resource and time-intensive nature of system development. The versatility of DRL agents to learn continuously and strategically adapt to shifting conditions underscores its powerful capability in refining operational efficiency. In high-stakes sectors where precise control is directly correlated to profitability and sustainability, DRL’s advanced algorithms pave the way for smarter, more efficient systems. This contrasts sharply with the more rigid configurations of traditional controllers, which often become obsolete when faced with unpredictable industrial challenges.

Future Prospects and Industry Adoption

The integration of DRL with online process analyzers and digital twins sets the stage for pioneering advancements across processing industries. This forward-thinking system architecture supports not only real-time adaptive control but also incremental learning—a critical capability in today’s fast-evolving technological landscape. With an emphasis on performance sustainability, DRL has already demonstrated its ability to dramatically reduce energy usage, emissions, and raw material waste. As data volumes surge and AI models continue to improve, DRL-based control systems are anticipated to gain greater autonomy, responding to operational fluctuations and broader market or regulatory shifts.

The potential for this technology’s expansion is vast, with its deployment currently seen from chemical production facilities to energy systems and advanced manufacturing units. This integration points toward a future where industries are not just automated but smart, capable of self-regulating in response to internal and external cues. As DRL and online analyzers become more ingrained in industrial operations, stakeholders will likely witness a significant shift in how manufacturing processes are controlled. This shift isn’t merely an upgrade; it represents an entire evolution in the logic underpinning industrial automation.

Real-World Impact and Future Implications

At the core of this tech evolution is the notion that Deep Reinforcement Learning (DRL), when paired with online process analyzers, presents a powerful alternative to traditional process control methods. Conventional approaches often depend on static models, lacking adaptability. DRL, however, enables industrial systems to continually learn and adapt, making it highly effective in complex environments marked by non-linearities and changing load conditions. By harnessing Machine Learning (ML) within digital twins—virtual simulations of physical processes—industries can explore, learn, and devise optimal control strategies without putting actual assets at risk. To fully capitalize on this strategy, a strong system design, a robust data infrastructure, and ongoing model refinement are essential.

Deep Learning models, including DRL, leverage historical data to uncover detailed dependencies among process variables. Still, this dependency on past data presents limitations, particularly when models face scenarios outside their trained statistical range. Industrial operations are often complex and non-linear, with multiple local minima requiring intensive computations to locate global optima, especially in real-time settings. Overcoming these challenges is vital for effective deployment in dynamic industrial contexts.