A comprehensive analysis of recent advancements from Harvard’s John A. Paulson School of Engineering and Applied Sciences reveals a groundbreaking mathematical framework for optimizing robotic joints, a development poised to significantly advance robotics, human-assistive devices, and biomechanics. This novel computational design approach fundamentally rethinks how robotic joints are created, shifting focus from complex software-based control to inherent mechanical intelligence. By embedding task-specific functionality directly into the physical structure of a robot’s joints, this method creates custom components precisely tailored for their purpose, leading to machines that are more efficient, graceful, and capable. This review will explore the evolution of this technology, its key features, performance metrics, and the impact it has already demonstrated on various applications.

Foundations of Mechanical Intelligence in Robotics

At the heart of this research is the principle of “mechanical offloading,” a design philosophy that moves beyond traditional software-heavy control systems. This approach embeds desired motions and force profiles directly into the physical geometry of a robot’s joints. Consequently, the centralized control system, or the robot’s “brain,” is freed from managing the low-level details of joint movement. Instead, it can concentrate on higher-level, task-oriented goals, resulting in a system that is more elegant and efficient both mathematically and mechanically.

This shift toward physically encoded instructions allows for a more targeted and precise application of energy. By embedding operational logic—such as where to output the most force during a walking stride—into the mechanics of the joint itself, the resulting robot can use its power with remarkable accuracy. This targeted energy use enables the integration of smaller, less powerful, and more energy-efficient actuators, as the joint’s custom geometry performs the heavy lifting of directing and modulating force. This allows for simpler and more robust systems by letting the hardware manage low-level motion profiles.

The Core Technology Redefining the Rolling Contact Joint

The key technological components enabling these mechanically intelligent robots are the innovative use of rolling contact joints and the computational framework developed to design them. While more conventional joints like bearings are prevalent, rolling contact joints—which consist of pairs of curved surfaces that roll against each other—offer distinct advantages such as minimal friction and high resistance to wear. The true breakthrough lies in transcending the limitations of traditional rolling joints, which are typically built from simple circular surfaces.

From Simple Circles to Complex Geometries

The Harvard framework fundamentally reimagines the shape and function of the rolling contact joint. It moves beyond simple circles to allow for the design and fabrication of noncircular, irregular shapes. This capability is transformative, as it means the joints can be programmed to follow highly specific, complex trajectories and to exhibit variable force transmission ratios throughout their range of motion. The joint itself becomes an active mechanical component rather than a passive pivot point.

This design process essentially works backward from a desired outcome. Engineers can specify a complex movement path and the exact force required at each point along that path. The computational model then generates the unique, noncircular surface geometries for the joint components that will produce precisely those properties. This allows a desired function to be programmed directly into the hardware, simplifying the control requirements and optimizing performance for a specific task.

A Novel Computational Design Framework

This revolutionary approach is made possible by a groundbreaking mathematical model that facilitates a “reverse-engineering” design process. Instead of starting with a joint and then programming a robot to use it effectively, the framework starts with the goal. This model is the engine that translates high-level task requirements into tangible, custom-fabricated hardware, making the design of such complex geometries feasible and repeatable.

The inspiration for this sophisticated methodology stemmed from a practical challenge: creating a soft robotic gripper capable of both gently conforming to an object and applying a strong, secure grip. The pursuit of a system that combines rigid structural links with soft, flexible joints led the team to explore the untapped potential of rolling contact joints. This exploration culminated in the development of a new, generalized design methodology that can be applied to a wide array of robotic and biomechanical challenges.

The Paradigm Shift Toward Integrated Design

The research highlights a significant and overarching trend in modern robotics: the move toward a more holistic and integrated approach to design. This marks a shift away from viewing a robot’s body as a passive frame and toward seeing it as an active participant in its own control and motion. This philosophy, often termed “embodied intelligence,” blurs the lines between hardware and software, creating systems where the physical form contributes directly to the machine’s behavior.

This integrated design approach challenges the long-held tradition of developing a robot’s mechanical structure and its control software as separate entities. By co-designing the body and the “brain,” engineers can create synergies that lead to unprecedented levels of performance and efficiency. The development of a versatile robotic gripper inspired this innovative methodology, proving that integrating function into form is key to overcoming complex manipulation challenges.

Demonstrated Performance in Real World Scenarios

To validate the mathematical framework, researchers constructed and tested two compelling prototypes that showcase the real-world applications of the technology. These prototypes, a knee-like joint for assistive devices and a high-efficiency industrial gripper, offer a practical look at the tangible benefits and performance gains achieved through this new design philosophy. The results provide strong evidence of the technology’s potential to solve long-standing challenges in both healthcare and manufacturing.

Human Assistive Devices The Optimized Knee Joint

The first prototype addressed a common problem in existing knee-assist devices and exoskeletons, which often use simple bearing joints. These standard joints fail to replicate the complex kinematics of a real human knee, which not only hinges but also rolls and glides. This mismatch can lead to painful misalignment and discomfort for the user. By mapping the motion path of a human knee and using their optimization algorithm, the team designed a custom joint that mimicked this natural movement.

The performance of the optimized knee joint was spectacular, demonstrating a 99% reduction in misalignment compared to standard devices. This result has profound implications for the future of assistive technologies. It suggests a path toward custom-tailored knee braces, exoskeletons, and even surgical joint replacements that are designed around an individual’s unique biomechanics, maximizing both comfort and efficacy.

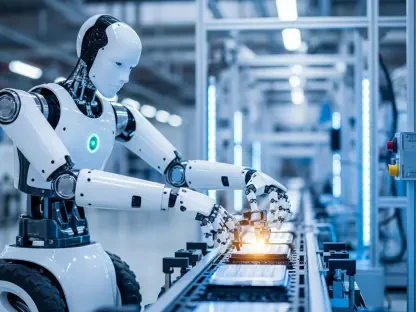

Industrial Robotics The High Efficiency Gripper

The second prototype, a two-finger robotic gripper, was engineered to demonstrate the framework’s capacity for task-specific force optimization. The joints were designed to deliver maximum gripping force that intelligently adapted to the size of the object being held. The performance of this prototype was then compared to a gripper of the same size built with standard circular joints and pulleys.

For the exact same input from its actuator, the gripper with the optimized, noncircular joints was able to securely hold more than three times the weight of the standard model. This dramatic improvement showcased the efficiency gains made possible by encoding functionality into the joint’s physical form. This has significant implications for industrial automation, where enhanced gripping force and efficiency can translate to lower energy consumption and the ability to handle a wider range of objects.

Challenges and Future Research Directions

While the foundational framework for designing these optimized joints is now established, hurdles remain in applying it to more complex systems. One significant challenge lies in extending the methodology to multi-joint robots where the motion of one joint directly influences others. Scaling up the manufacturing of these custom-shaped components to meet industrial demands also presents a practical obstacle that will require further innovation in fabrication techniques.

Ongoing development efforts are focused on overcoming these challenges to apply this methodology across a wider spectrum of real-world robotic systems. Future work will likely explore integrating advanced materials and expanding the computational model to handle dynamic, multi-axis movements. Success in these areas will be critical for unlocking the technology’s full potential in creating sophisticated robots for complex environments.

The Future of Mechanically Intelligent Systems

Looking ahead, this technology opens numerous avenues for future breakthroughs with long-term societal impact. The ability to design joints for specific functions could lead to the creation of highly specialized robots optimized for walking, jumping, or intricate manipulation tasks. Such robots could navigate difficult terrain or perform delicate operations with a level of grace and efficiency currently unattainable.

In the medical field, the potential for next-generation personalized devices is immense. Beyond custom knee braces, this approach could revolutionize prosthetic limbs, surgical robotics, and rehabilitative exoskeletons, making them more natural and effective for each user. Furthermore, the framework provides a new tool for scientists to study and replicate the complex biomechanics of animal locomotion, deepening our understanding of the natural world and inspiring new robotic designs.

Conclusion A New Era for Embodied Intelligence

The research into optimized rolling contact joints represented a pivotal moment in robotics, confirming that designing intelligence directly into a machine’s physical structure yielded vastly more efficient and precisely tuned systems. The successful demonstrations of the assistive knee joint and the high-force gripper provided tangible proof that this integrated design philosophy could solve real-world problems. This work established a powerful new paradigm, leaving a legacy that moved the fields of robotics and assistive technology into a new era of embodied intelligence.