The humanoid robot, long a fixture of science fiction and dazzling tech demonstrations, is now standing at the precipice of a profound transformation from a captivating spectacle into a functional tool. This review explores the evolution of the technology from public displays of agility to practical application, its key hardware and software components, performance metrics, and the impact it is beginning to have on industrial applications. The purpose of this review is to provide a thorough understanding of the technology’s current capabilities, its significant challenges, and its potential future development.

From Acrobatic Displays to Assembly Lines

The era of judging humanoid robots by their ability to perform backflips or dance is rapidly drawing to a close. For years, the industry captivated audiences with impressive physical feats, but a clear and decisive shift is underway. The focus has moved away from novelty and toward necessity, driven by a growing demand for robots that can perform meaningful, productive work in environments designed for people. This transition reflects a maturation of the market, where stakeholders are now asking not what a robot can do for a demonstration, but what it can do for an operation.

This pivot is especially relevant in a global economy increasingly reliant on automation. Humanoid robots offer a unique proposition: the ability to integrate into existing human-centric workflows without requiring a complete and costly overhaul of factories, warehouses, or logistics centers. Their form factor is their key advantage, allowing them to navigate stairs, open doors, and operate tools intended for human hands. The industry is no longer just building impressive machines; it is now tasked with creating viable, robotic colleagues.

Analyzing the Great Technology Divide

A Body Engineered for Action

The physical hardware of modern humanoid robots has reached an extraordinary level of sophistication. The engineering behind bipedal locomotion, dynamic balancing, and fine motor control has largely been mastered, enabling machines to walk, run, and even perform complex acrobatics with a grace that rivals human athletes. These physical platforms are a testament to decades of progress in mechanical engineering, materials science, and actuator technology.

This advanced physical prowess demonstrates that the “body” of the humanoid is no longer the primary obstacle to its practical deployment. Companies have successfully engineered systems capable of navigating complex terrains and manipulating a wide array of objects. The hardware is, for all intents and purposes, ready for work. The core challenge has therefore shifted from the physical shell to the intelligence that must inhabit it.

The Lagging Intelligence Within the Machine

The most significant bottleneck hindering the widespread adoption of humanoid robots lies not in their mechanical bodies, but in their artificial “brains.” Current AI models, including the Large Language Models (LLMs) that have revolutionized digital information processing, are fundamentally ill-suited for the complexities of physical interaction. These models are trained on vast datasets of text and images from the internet, which provides no intuitive understanding of physics, cause-and-effect, or spatial navigation in the three-dimensional world.

A robot trained on this abstract data is like a person who has only read books about the world but has never stepped outside. It lacks the grounded, experiential knowledge required to handle unexpected situations or manipulate objects with genuine understanding. This gap between advanced hardware and underdeveloped AI is the central problem the industry is now racing to solve.

Pioneering New Pathways in AI Development

The Critical Role of Embodied Learning

To bridge the chasm between hardware and software, the industry is coalescing around the concept of embodied learning. This principle posits that for a robot to acquire meaningful intelligence about the physical world, it must learn through direct experience. Abstract data is insufficient; the robot must gather knowledge while operating “inside a body,” interacting with its environment to understand the consequences of its actions.

This hands-on approach is considered essential for developing the general-purpose capabilities that would make humanoids truly useful. By physically performing tasks, the robot builds a rich, multi-modal understanding of the world that connects vision, touch, and movement. It is through this process of embodied experience that a machine can move beyond pre-programmed routines and begin to exhibit genuine adaptability and problem-solving skills.

Forging Alliances for Data and Development

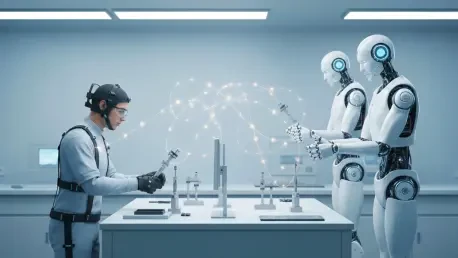

Generating the massive datasets required for embodied learning has spurred innovative new strategies and powerful collaborations. Some firms are developing novel data-collection methods, such as outfitting human workers with motion-capture suits, cameras, and haptic gloves to record first-person perspectives of manual tasks. This creates a library of real-world interactions that can be used to train robotic systems.

Moreover, a trend of strategic partnerships is accelerating progress. Robotics startups are collaborating with technology giants like Amazon and Meta, leveraging their immense computational resources and AI expertise to build more sophisticated control platforms. These alliances are crucial for tackling the immense scale of the data and software challenges, combining specialized robotics knowledge with world-class AI research and development.

Charting the Course for Real-World Deployment

The Strategic Focus on Industrial Spaces

The initial proving grounds for practical humanoid robots are factories and warehouses. This strategic choice is driven by pragmatism. These environments are structured, task-oriented, and, most importantly, already built around human workers. A robot with a human-like form can seamlessly integrate into these existing spaces, using the same tools, navigating the same aisles, and working alongside human teams without demanding a costly facility redesign.

This approach significantly lowers the barrier to entry for adoption. Companies like Hyundai are already exploring the integration of humanoids from partners like Boston Dynamics into their automotive manufacturing plants. By targeting these industrial applications first, the industry can demonstrate tangible value and build a foundation for broader deployment in the future.

The Illusion of Autonomy Versus Reality

A crucial distinction must be made between true autonomy and the teleoperation often seen in public demonstrations. Many seemingly intelligent and independent robotic actions are, in fact, being guided in real time by a human operator. This “human-in-the-loop” approach, where a person remotely controls the robot’s movements, creates a powerful illusion of autonomy that can set unrealistic expectations about the technology’s current state.

While teleoperation is a valuable tool for data collection and for handling tasks that are currently beyond the robot’s autonomous capabilities, it is not a long-term solution. Recognizing the difference is vital for investors, businesses, and the public to accurately assess the progress of the technology and understand that the journey toward full, unassisted autonomy is still ongoing.

Confronting the Hurdles on the Path to Adoption

The Unsolved Challenge of Data Collection

Despite innovative strategies, the sheer scale of the data-gathering challenge remains a formidable obstacle. Training a robot to be reliable and adaptable in an unstructured environment requires an astronomical amount of high-quality, real-world interaction data. Collecting and labeling this data is not only technically difficult but also incredibly time-consuming and expensive.

Achieving the level of robustness needed for a robot to safely and effectively work alongside humans means preparing it for countless edge cases and unexpected events. This requires a data pipeline that is far more complex and resource-intensive than those used for training language models, and it continues to be a primary focus of research and development across the industry.

From Return on Novelty to Return on Investment

The humanoid robotics market is facing a significant commercial hurdle: moving beyond the “wow factor” to prove its economic viability. For years, the novelty of seeing a robot perform an impressive feat was enough to generate interest and investment. However, the market has matured, and the conversation is now squarely focused on productivity and profitability.

Investors and potential customers are demanding a clear return on investment. A humanoid robot must demonstrate that it can perform tasks more efficiently, more safely, or more consistently than current methods to justify its high cost. This pressure is forcing companies to shift their priorities from flashy demonstrations to pilot programs that can deliver measurable, tangible business value.

Projecting the Milestones on the Road Ahead

Near-Term Goals in Structured Environments

In the immediate future, the primary goal for the humanoid robotics industry is to prove its value through successful pilot deployments in controlled industrial settings. The key milestone will not be a new acrobatic stunt, but rather a robot consistently and reliably performing a mundane but valuable task on a factory floor or in a warehouse for an extended period.

These initial deployments will be critical for gathering performance data, refining software, and demonstrating a clear ROI. Success in these structured environments will build the commercial confidence and operational experience needed to tackle more complex and less predictable applications in the years to come.

The Long-Term Vision of a General-Purpose Assistant

Looking further ahead, the ultimate ambition for humanoid robotics remains the creation of a truly general-purpose machine. The goal is to develop robots that are not just specialized for a single industrial task but are capable of assisting humans in a wide variety of contexts, from commercial services to domestic chores and elder care.

This long-term vision involves creating a machine that is not intended to perfectly replicate human emotion or consciousness, but to serve as a highly capable physical assistant. While some teams continue to push the boundaries of physical performance, like training a robot to run a marathon, the overarching aim is to channel that capability into productive, helpful, and versatile applications that will eventually integrate these machines into daily life.

Concluding Assessment a Pivotal Moment for the Industry

This review has found that the humanoid robotics industry is at a defining inflection point. The mechanical hardware has achieved a remarkable level of maturity, capable of a wide range of dynamic and dexterous actions. However, this progress has starkly highlighted the profound gap between physical capability and the artificial intelligence required for practical, autonomous operation.

The industry’s focus has now decisively shifted from engineering better bodies to developing smarter brains. The path forward is being paved with new approaches like embodied learning, innovative data-gathering techniques, and strategic collaborations designed to solve the immense software challenge. As humanoids begin to transition from laboratory curiosities to pilot programs on factory floors, the central mission is no longer to entertain, but to deliver tangible, economic value. The coming years will be critical in determining how quickly these remarkable machines can move from performing for a crowd to working as a member of the team.