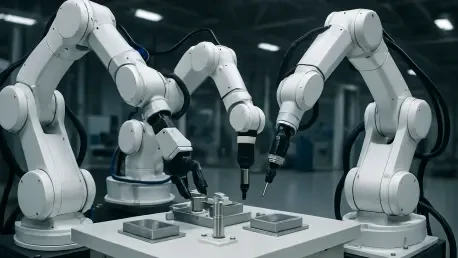

Imagine stepping into the future of industrial automation, where robotic arms move in perfect harmony, like dancers in a meticulously choreographed performance. At the forefront of this revolution is Oscar Vail, a technology expert whose passion for robotics, quantum computing, and open-source innovation has positioned him as a thought leader in the field. Today, we’re diving into his insights on RoboBallet, a groundbreaking system that’s redefining how multiple robots collaborate in busy factory settings. Our conversation explores the inspiration behind this technology, the AI magic that powers it, its transformative potential for manufacturing, and what lies ahead for this elegant solution.

Can you give us a quick overview of what RoboBallet is and why it’s such a game-changer for industrial robotics?

Absolutely. RoboBallet is a cutting-edge system designed to coordinate multiple robotic arms in shared, obstacle-filled environments like factory floors. It uses advanced AI to automate the planning of their movements, ensuring they work together without collisions while maximizing efficiency. What makes it a game-changer is its ability to handle complex setups with up to eight robots at once, generating plans in seconds—something that used to take human programmers hundreds of hours. It’s a huge leap toward smarter, more adaptive manufacturing.

How did the idea for RoboBallet come about, and was there a specific challenge in manufacturing that sparked this innovation?

The idea stemmed from a persistent pain point in industrial settings: coordinating multiple robots in tight spaces. Traditionally, human specialists manually plan every movement, which is incredibly time-consuming and prone to errors, especially as the number of robots increases. We saw a need for a system that could automate this process with speed and precision, allowing factories to adapt quickly to changes. The vision was to create a solution that mimics the harmony of a dance, where each robot knows its role and moves seamlessly with the others.

Can you walk us through how RoboBallet leverages AI techniques like graph neural networks to help robots understand their surroundings?

Sure. Graph neural networks are a type of AI model that excels at handling data structured as interconnected points, or graphs. In RoboBallet, we treat the factory environment—robots, obstacles, and tasks—as a network of points and relationships. This allows the system to map out the space and reason about how robots can move without interfering with each other. It’s like giving the robots a spatial awareness that helps them navigate and collaborate effectively, even in cluttered or unfamiliar setups.

What role does reinforcement learning play in making robots perform tasks faster and smarter with RoboBallet?

Reinforcement learning is all about teaching through trial and error. In RoboBallet, the system learns by simulating countless scenarios, getting a virtual ‘reward’ when it completes tasks, with bigger rewards for doing so quickly. Over time, it figures out the most efficient ways to coordinate movements and solve problems. This approach means the robots don’t just follow pre-programmed paths—they adapt and optimize their actions on the fly, getting smarter with every iteration.

What sets RoboBallet apart from earlier systems that attempted to coordinate multiple robots?

Older systems often relied on rigid, traditional planning algorithms that couldn’t scale beyond a couple of robots. As complexity grew, these methods bogged down because they tried to calculate every possible interaction, which becomes impractical fast. RoboBallet, on the other hand, uses a flexible, AI-driven approach with graph-based learning. This lets it generalize coordination principles instead of memorizing specific scenarios, so it can handle larger teams of robots—like eight arms—without losing efficiency or accuracy.

Why did you choose the name ‘RoboBallet,’ and how does it reflect the system’s functionality?

The name ‘RoboBallet’ captures the elegance and synchronization we aimed for. Just like ballet dancers move in perfect harmony, each robotic arm in our system operates with precision and awareness of its teammates. It’s not just about avoiding collisions; it’s about creating a fluid, purposeful interaction among robots. The name reflects our goal of turning chaotic factory floors into a beautifully orchestrated performance of technology.

How does RoboBallet’s speed in planning robot movements compare to the traditional manual process, and what does that mean for factories?

RoboBallet plans movements hundreds of times faster than real-time, while manual programming by humans can take hundreds of hours per task set. For example, in a factory setting, a layout change or new task that might have taken days to reprogram can now be planned in seconds. This speed means factories can adapt almost instantly to disruptions or redesigns, slashing downtime and boosting productivity in ways that were previously unimaginable.

In which industries or tasks do you see RoboBallet making the biggest impact right now?

Right now, RoboBallet is poised to transform industries like car manufacturing and electronics assembly, where precision and coordination in tight spaces are critical. Think of assembling complex components on a production line—RoboBallet can streamline that process significantly. Beyond these, there’s potential in more unconventional areas like robotic construction for building houses, where multiple robots could work together on dynamic, large-scale projects. Anywhere robots need to collaborate closely, this system can make a difference.

How does RoboBallet manage to adapt so quickly when a robot fails or the factory layout changes?

The secret lies in its AI architecture. Because RoboBallet learns general coordination principles rather than specific setups, it can re-evaluate the environment and recalibrate plans in real-time. If a robot fails, the system instantly redistributes tasks among the remaining robots. If the layout changes, it remaps the space using its graph-based understanding. This adaptability happens in seconds, ensuring operations keep running smoothly without lengthy reprogramming.

What’s your forecast for the future of multi-robot coordination systems like RoboBallet in industrial automation?

I’m incredibly optimistic. Systems like RoboBallet are just the beginning. I foresee them evolving to handle even more complex tasks—think pick-and-place operations or painting, with robots of varying capabilities working together. As AI continues to advance, we’ll see these systems integrate task dependencies and manage diverse teams across entire supply chains. The ultimate goal is fully autonomous factories that can reconfigure themselves dynamically, driving efficiency and innovation to unprecedented levels.