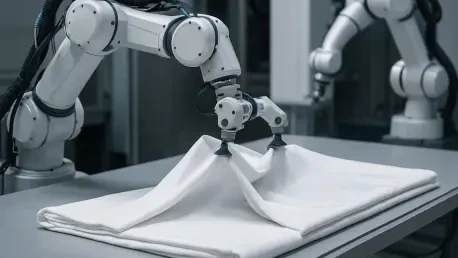

Imagine a robot that can morph its shape like a living organism, adapting to rugged terrains or delicately grasping objects with precision, all without the constraints of rigid structures. This is no longer a concept confined to science fiction but a reality brought to life by cutting-edge advancements in robotic folding sheet technology. Developed by pioneering researchers, this programmable sheet offers a glimpse into a future where robots are not bound by fixed designs but can dynamically respond to their environments. This review delves into the intricacies of this transformative technology, exploring its core features, real-world applications, and the challenges that lie ahead in its journey toward widespread adoption.

Core Features and Technical Breakthroughs

Heat-Sensitive Folding Mechanism

At the heart of this robotic folding sheet lies an innovative heat-sensitive folding mechanism, drawing inspiration from the ancient art of origami. By embedding 308 resistors into a 40 cm² sheet, the technology achieves precise control over folding angles, ranging from -87° to 109°. Heat plays a pivotal role in triggering shape transformation, allowing the sheet to adapt its form with remarkable accuracy and respond to environmental demands in real time.

This mechanism enables dynamic adaptability, a crucial factor in environments where traditional robots with static hinges often falter. The ability to fold and unfold on command opens up possibilities for tasks requiring intricate movements, such as navigating uneven surfaces or manipulating objects of varying shapes. Such precision underscores the potential of this technology to redefine robotic design principles.

Dual-Purpose Sensor and Heater Integration

Another standout feature is the integration of dual-purpose electrical components that function as both heaters and sensors. These elements provide real-time feedback, ensuring stability across a broad temperature spectrum from 30°C to 170°C. This dual functionality not only enhances the sheet’s performance but also streamlines the overall design by reducing the need for separate systems.

The impact of this integration is profound, as it minimizes complexity while maximizing efficiency. By embedding sensing and actuation into a single framework, the technology achieves a level of responsiveness that is critical for applications in unpredictable settings. This balance of simplicity and sophistication marks a significant leap forward in robotic engineering.

Performance in Dynamic Environments

The performance of the robotic folding sheet aligns closely with current trends in robotic flexibility, particularly the industry’s push toward autonomy in challenging conditions. Unlike conventional robots limited by fixed structures, this sheet demonstrates an ability to adapt seamlessly, whether crawling across varied terrains or interacting with diverse objects. Its capacity to handle tasks in dynamic environments positions it as a frontrunner in the evolution of autonomous systems.

Specific demonstrations reveal the sheet’s versatility, from traversing rough surfaces to grasping items like petri dishes and wooden sticks with finesse. Such capabilities highlight its potential to operate in scenarios where adaptability is paramount, offering a stark contrast to traditional robotic limitations. This performance sets a benchmark for future developments in the field.

Real-World Applications Across Sectors

The practical utility of this technology spans multiple industries, showcasing its transformative potential in real-world settings. In exploration, the sheet’s ability to crawl over uneven landscapes makes it an ideal candidate for missions in remote or hazardous areas, such as planetary surfaces or disaster zones. Its adaptability ensures it can navigate obstacles that would impede conventional robots.

In the realm of smart healthcare, the technology offers promising applications, such as precise manipulation of medical tools or tissues during procedures. Additionally, its integration into haptic displays could revolutionize user interfaces by providing tactile feedback in virtual environments. These diverse use cases illustrate the broad impact this innovation could have on enhancing operational efficiency across sectors.

Challenges Hindering Full Potential

Despite its impressive capabilities, the robotic folding sheet faces notable challenges that must be addressed for broader implementation. Limitations in material science pose a significant barrier, as current materials may not withstand prolonged exposure to extreme conditions or repeated folding cycles. Structural design constraints also limit the complexity of shapes the sheet can achieve, restricting its functionality in certain contexts.

Ongoing research aims to overcome these hurdles by exploring advanced materials and refined designs that can enhance durability and versatility. Regulatory barriers, particularly in industries like healthcare, may also slow adoption, as stringent standards for safety and reliability must be met. These obstacles highlight the need for continued innovation and collaboration to unlock the technology’s full potential.

Future Outlook and Potential Breakthroughs

Looking ahead, the future of robotic folding sheet technology appears promising, with potential breakthroughs on the horizon. Advances in material science could lead to the development of more resilient and flexible sheets capable of withstanding harsher environments. Enhanced design techniques might also enable more intricate folding patterns, expanding the range of tasks the technology can perform.

The long-term impact could be transformative, particularly in fields like space exploration, where adaptive robots are essential for navigating uncharted terrains, or in medical robotics, where precision is critical. Over the next few years, from 2025 to 2027, sustained investment in research and development could accelerate these advancements, paving the way for a new era of responsive robotic systems.

Final Thoughts on a Pioneering Technology

Reflecting on this review, the journey of robotic folding sheet technology proves to be a remarkable stride in the realm of autonomous systems. Its innovative features and demonstrated performance in varied applications underscore a shift away from static robotic designs. The exploration of its capabilities reveals a tool that adapts with precision and versatility, tackling challenges that once seemed insurmountable.

Moving forward, the focus shifts to actionable steps, such as prioritizing research into durable materials and streamlined designs to overcome existing limitations. Collaboration between engineers, material scientists, and industry stakeholders emerges as a vital strategy to address regulatory and technical barriers. This technology’s evolution promises to inspire a wave of adaptive solutions, setting a foundation for robots that could truly mirror the responsiveness of natural systems.