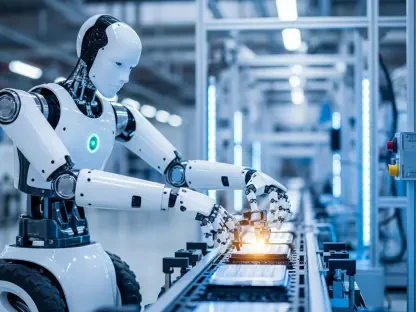

In the midst of technological evolution, a fascinating development in robotic dexterity is capturing attention worldwide. Robots equipped with slip-prevention technology are increasingly stepping into dynamic environments, handling delicate and complex tasks with precision akin to human touch. With automation poised to reshape industries such as manufacturing, healthcare, and logistics, there emerges a compelling need for robots to manipulate objects without accidentally dropping or damaging them. This nuanced control, ensuring safety and efficiency, is a breakthrough in industrial automation that challenges existing paradigms and sets new standards.

Exploring Robotic Slip Prevention Technology

Robotic slip-prevention techniques stand at the frontier of technological advancement. Anchored in principles mirroring human reflexes, this innovation incorporates a proactive slip control architecture, signaling a shift from traditional methods. The system evolves from just maximizing grip force to intelligently modulating dexterity, akin to how humans adjust grip upon sensing an object’s slip. Within the broader technological landscape, this approach promises immense potential in enhancing the robots’ ability to manage delicate operations without compromising the integrity of fragile items.

The system is built upon components that enable real-time adjustment of robotic movements. It harnesses advanced sensors and algorithms to predict slippage before it occurs, optimizing the function in diverse applications. It emerges as a groundbreaking solution, suggesting transformative prospects for industries reliant on precision and care, positioning robotics firmly within realms traditionally dominated by human capability.

Proactive Slip Control Architecture: A Game-Changer

Proactive slip control forms the cornerstone of advanced robotic manipulation, essentially redefining how robots interact with varied objects. Unlike the conventional approach, which often damages fragile items due to increased pressure, this architecture permits careful handling through subtle movement adjustments. Essential to its operation is a system allowing the robot to perceive and respond to imminent slippage without delay, maintaining secure contact and precision even with asymmetrical or slippery items.

This meticulous balance, an innovation led by experts such as Dr. Amir Esfahani, signifies a move toward robots achieving unparalleled dexterity. It addresses a crucial challenge in robotic handling: ensuring stability amidst complexity. The implications of this technology are profound, paving the way for applications where robots act as reliable partners in handling precision-demanding tasks across varied settings—from surgical assistance in healthcare to intricate component assembly in manufacturing.

Tactile Forward Model: Elevating Precision

The tactile forward model enhances robotics by allowing prediction and adaptation to potential slips based on ongoing movements. By incorporating predictive control, robots can foresee and adjust to avoid mishaps, mirroring human-like responsiveness. The system demonstrates versatility as it successfully operates on objects and paths beyond its initial training, illustrating the capability to generalize and adapt.

This feature offers invaluable insights into robotic functionality, promising advancements across robotics-heavy industries. Applications show innovation not just theoretically but manifest in practical deployment. There is now a tangible link between theoretical modeling and real-world execution, demonstrating robotics’ growing potential to seamlessly integrate into environments requiring precision.

Emerging Trends and Developments

The field of robotic slip prevention witnesses rapid development, with trends expediting its adoption. As industries lean more toward precision automation, demands for technologies that provide reliable grip control surge. Collaboration across universities and research entities fosters refinement and encourages breakthroughs, indicating shifts in future trajectories.

These emerging trends promise to reshape robotics, offering solutions to long-standing challenges related to dexterity. As data-driven machine learning advances, robotics increasingly adapts to complex environments, indicating future developments that could elevate automation reliability further.

Applications in Diverse Realms

Robotic slip prevention technology sees varied applications, marking influential changes across sectors. Industries such as healthcare, manufacturing, and logistics embrace this technology to improve operational proficiency. Noteworthy implementations involve robots handling surgical instruments, assembling intricate components, or managing irregularly shaped packages, witnessing where innovation leads to enhanced safety and reliability.

Each use case underscores the pioneering potential of robots equipped with slip prevention. Benefiting from improved adaptability, these technologies hold promise for implementations extending into everyday settings, highlighting a trajectory towards increasingly autonomous robotic assistants.

Challenges and Limitations Ahead

Despite breakneck progress, robotic slip prevention technology encounters challenges. Technical hurdles and regulatory constraints create barriers to widespread adoption. Recognizing these challenges, researchers and industry leaders are striving toward refinement and overcoming limitations through rigorous testing and innovation.

Ongoing development efforts aim to bridge these obstacles while ensuring adherence to standards and adaptability in varying environments. Addressing current limitations is essential for harnessing the technology’s full potential, essential to further integrate robotics into sectors reliant on precision and reliant systems.

Looks to the Future

The trajectory of robotic slip prevention technology suggests an exciting future. Anticipated advances may unlock capabilities beyond current limitations, surpassing conventional boundaries in automated precision. Future developments foresee robots evolving from mere mechanical aids to sophisticated partners capable of complex manipulations.

Innovators push toward refining this technology further, focusing on adaptability in unforeseen circumstances and empowering robots with enhanced capabilities. The long-term impact may redefine robotic roles across industries, compelling shifts toward fully integrated robotic systems within professional and personal spheres.

Final Thoughts and Verdict

The journey into the realm of robotic slip prevention unveils a significant milestone in advancing robotic capabilities, providing innovative solutions to long-standing challenges in manipulation dexterity. Offering insights into future potential and encouraging refinement in robotic systems, this technology successfully reshapes perspectives on automation. The technology has heralded a new age of robotic functionality, potentially transforming how robots interact within diverse environments, underscoring an exciting future of possibilities.