Picture a future where robots can handle objects with the same delicate precision as a human hand, sensing pressure and adjusting grip in an instant to avoid a slip or a crush. This once-distant dream is now on the horizon thanks to a remarkable breakthrough from researchers at the University at Buffalo. A newly developed fabric-based sensor is enabling robots to emulate the tactile sensitivity of human skin, detecting subtle changes in pressure, slippage, and movement in real time. This advancement is poised to redefine the capabilities of robotic systems, offering a transformative impact across industries that demand high precision and human-like dexterity. From intricate surgical procedures to seamless manufacturing processes, the potential for this technology to reshape human-robot interaction is profound, marking a significant milestone in the journey toward more intuitive and adaptable machines.

Technical Innovation Behind the Sensor

Revolutionizing Robotic Touch

The foundation of this groundbreaking technology lies in a fabric-based sensor crafted from electronic textiles, commonly referred to as E-textiles. This innovative material leverages the tribovoltaic effect, a process where friction between different surfaces generates a direct-current signal. What sets this sensor apart is its astonishing response time, ranging from 0.76 to 38 milliseconds, which closely mirrors the reaction speed of human touch receptors, typically between 1 and 50 milliseconds. Such rapid responsiveness allows robots to detect and react to tactile stimuli with a level of sensitivity that was previously unattainable. This capability is not merely a technical achievement; it represents a fundamental shift in how robotic systems can interact with their environment, performing tasks that require finesse and real-time adjustments with unprecedented accuracy.

Beyond the speed, the significance of mimicking human touch cannot be overstated. The sensor’s design enables robots to perceive nuanced tactile feedback, such as the texture of a surface or the subtle shift of an object in grip. This breakthrough addresses a long-standing limitation in robotics, where mechanical rigidity often hindered delicate operations. By integrating this technology, robotic systems can now approach tasks with a gentleness akin to human hands, opening up possibilities for applications where precision is paramount. Researchers at the University at Buffalo have emphasized that this development is a crucial step toward creating machines that can operate in harmony with human expectations, fundamentally altering the landscape of robotic functionality.

Real-Time Grip Adjustments

One of the most compelling demonstrations of this sensor technology is its integration into 3D-printed robotic fingers connected to a compliant gripper. In a notable test, the sensor detected slippage when a copper weight was removed from the gripper’s hold, triggering an immediate adjustment in grip force to secure the object without causing damage. This real-time adaptability showcases the sensor’s potential to revolutionize how robots handle dynamic and unpredictable scenarios. Unlike traditional robotic grippers that rely on pre-programmed responses, this technology allows for instantaneous feedback and correction, ensuring that objects are neither dropped nor crushed. Such precision is a game-changer for industries where even the smallest error can have significant consequences.

The implications of this adaptive grip control extend far beyond a single demonstration. It paves the way for robotic systems to undertake tasks requiring intricate motor skills, from assembling delicate electronics to handling fragile materials in medical settings. The ability to adjust grip force on the fly means robots can now respond to real-world variables with a level of sophistication previously reserved for human hands. As highlighted by the research team, this advancement brings robotic functionality closer to biological benchmarks, offering a glimpse into a future where machines can seamlessly integrate into roles that demand tactile nuance. The potential for safer and more efficient operations across various fields is immense, setting a new standard for robotic design and interaction.

Applications and Industry Impact

Transforming Key Sectors

The scope of this sensor technology stretches across multiple industries, each standing to gain from enhanced robotic precision. In robotic surgery, for instance, the ability to control grip with near-human sensitivity could significantly improve the safety and accuracy of procedures. Surgeons using robotic tools equipped with this sensor could manipulate delicate tissues with reduced risk of unintended damage, leading to better patient outcomes. Similarly, in the realm of prosthetics, this innovation promises artificial limbs that respond more intuitively to users’ movements, offering a lifelike experience that enhances mobility and independence. The potential to transform lives through such applications underscores the far-reaching impact of this technological leap.

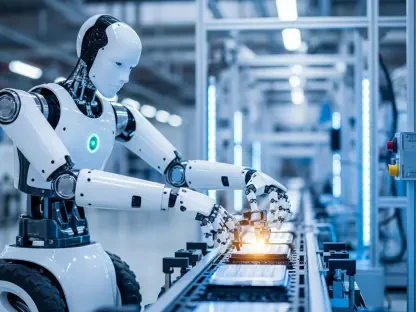

Manufacturing is another sector poised for disruption, as robots with advanced tactile sensors can handle fragile components and adapt to varying conditions alongside human workers. This capability fosters smoother collaboration, allowing machines to take on roles that require careful handling without sacrificing efficiency. However, the journey to widespread adoption is not without hurdles. Challenges such as ensuring compatibility with existing robotic systems and scaling production for broader use remain significant. Despite these obstacles, the research team remains committed to overcoming them, viewing these issues as stepping stones toward a more integrated and capable robotic future across industries.

Future Challenges and Refinement

Looking ahead, the path to fully realizing the potential of this sensor technology involves addressing several critical challenges. Compatibility with diverse robotic platforms is a primary concern, as seamless integration into existing systems is essential for practical deployment. Additionally, scalability poses a hurdle, as producing these sensors at a volume and cost suitable for widespread use requires innovative manufacturing approaches. Durability in real-world environments is another key issue, as the sensors must withstand continuous use without degrading in performance. Tackling these challenges is vital to ensuring that the technology can move from research labs to real-world applications with consistent reliability.

To address these issues, the research team plans to incorporate reinforcement learning into the sensor’s control algorithms, aiming to enhance adaptability across various robotic systems. This approach could refine how the sensor processes tactile data, making it more versatile in dynamic settings. The optimism surrounding these plans reflects a broader vision of a future where robots and humans collaborate with unprecedented synergy. As solutions to current limitations emerge, the technology holds the promise of reshaping industries valued at billions, redefining efficiency and safety standards. Reflecting on the strides made, it’s evident that the groundwork laid by this innovation has already sparked a shift, setting the stage for even greater advancements in the years ahead.