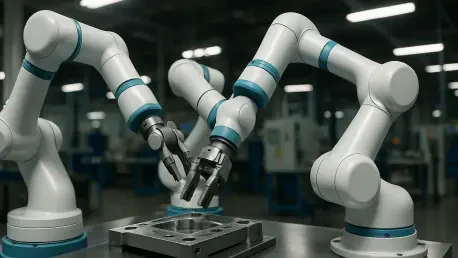

What if a bustling warehouse could operate without a single human touch, with robots gliding past each other, dodging obstacles, and reallocating tasks in perfect harmony? This isn’t a distant dream but a reality unfolding in cutting-edge facilities today. Across industries, from logistics to healthcare, a silent revolution is taking place as robots begin to think and act as one, powered by shared intelligence. This technology promises to redefine efficiency, slashing downtime and errors while tackling challenges too complex for lone machines. Dive into the world of collaborative robotics, where a collective brain is transforming the impossible into the everyday.

The Power of a Collective Mind

At the heart of this transformation lies a simple yet profound iderobots are stronger together. Standalone machines, while impressive, often stumble in dynamic environments where unpredictability reigns. Shared intelligence bridges this gap by enabling robots to communicate in real-time, adapt to sudden changes, and distribute workloads seamlessly. In settings like busy distribution centers, this means packages move faster and safer, with minimal human oversight. The significance of this shift cannot be overstated—it’s a direct response to the global demand for scalable automation in an era where speed and precision are non-negotiable.

Industries are already feeling the impact of this collaborative approach. Consider hospitals, where robots equipped with shared intelligence could deliver medications across wards, adjusting routes instantly if a hallway becomes crowded. This isn’t just about replacing human labor; it’s about enhancing safety and freeing up staff for critical, creative roles. As automation needs grow, particularly in sectors grappling with labor shortages, the ability of robots to work as a unified team offers a lifeline, promising to reshape operational landscapes with unprecedented efficiency.

Unpacking the Mechanics of Robotic Collaboration

The magic of shared intelligence rests on several innovative pillars that enable robots to function as a cohesive unit. Autonomous navigation stands out as a cornerstone, allowing robots to chart optimal paths through complex spaces like warehouses using advanced algorithms. Simulation tools such as Gazebo play a vital role, training robots in virtual environments to handle real-world obstacles before deployment. This preparation ensures they can pivot instantly—whether avoiding a spilled crate or rerouting during peak activity—keeping operations smooth and error-free.

Another critical element is dynamic decision-making, guided by behavior trees. These frameworks act as decision roadmaps, helping robots respond to challenges on the fly, from sidestepping collisions to signaling for assistance during a malfunction. Equally important is precision, achieved through computer vision technologies like ArUco markers, which provide localization accuracy within 2.5 centimeters. Add to this intelligent task allocation—where assignments go to the nearest available robot, with instant reassignment during failures—and the result is a system that thrives on collaboration rather than isolation.

Real-World Impacts and Expert Insights

Voices from the forefront of robotics paint a compelling picture of shared intelligence in action. Francisco Yumbla, a researcher from ESPOL, has contributed to a ROS2-based framework that demonstrates remarkable scalability, maintaining performance across teams of five to fifteen robots. Published studies in reputable journals highlight how these robots navigate intricate lab setups with flawless coordination, adapting to sudden changes without missing a beat. Yumbla notes, “The ability to distribute tasks dynamically transforms efficiency, especially in unpredictable environments.”

Test scenarios further validate this potential across diverse fields. In simulated restaurant settings, robots deliver dishes, seamlessly covering for each other if one encounters a delay. Industrial simulations show robots transporting packages in sprawling warehouses, avoiding congestion through real-time communication. These outcomes underscore a key truth: shared intelligence isn’t just a concept but a proven solution, ready to tackle real challenges with measurable results, from reduced downtime to enhanced safety protocols.

Bridging Theory to Practice in Diverse Sectors

The practical applications of this technology span a wide array of industries, each with unique demands. In logistics, shared intelligence enables robot fleets to optimize shipment handling, ensuring goods move through sorting facilities at record speeds. Healthcare facilities benefit as well, with robots coordinating to transport supplies or assist in patient care, minimizing errors in high-stakes environments. Even cultural spaces like museums are exploring autonomous guided tours, where robots adapt narratives based on visitor flow, enhancing engagement.

Beyond specific use cases, the broader implication is a shift in labor dynamics. By automating repetitive tasks through collaborative systems, human workers can focus on strategic roles that require empathy or innovation. This reallocation isn’t about displacement but empowerment, allowing industries to address skill shortages while maintaining productivity. As simulations continue to mirror real-world success, the evidence mounts that shared intelligence can redefine operational standards across the board.

Steps to Embrace the Robotic Revolution

For businesses eager to tap into this potential, adopting shared intelligence doesn’t have to be daunting. Starting with simulation platforms like Gazebo offers a low-risk way to train robots in virtual spaces, ironing out kinks before they hit the floor. Leveraging open-source frameworks such as ROS2 further simplifies the process, providing customizable tools that suit needs ranging from hospitality to heavy industry. This accessibility ensures that even smaller enterprises can experiment without breaking the bank.

Scaling up requires a strategic mindset—begin with a small robot team and expand gradually, ensuring the system adapts without losing efficiency. Prioritizing real-time adaptation through behavior trees and computer vision also minimizes disruptions, keeping operations fluid in dynamic settings. These actionable steps form a clear path for industries to integrate collaborative robotics, turning a cutting-edge concept into a practical asset that drives growth and innovation in an increasingly automated world.

Reflecting on a Transformative Journey

Looking back, the strides made in robotic shared intelligence marked a turning point for automation. What began as a challenge to overcome the limitations of individual machines evolved into a robust framework where robots collaborated with precision and adaptability. The insights from researchers and the success of real-world simulations underscored a pivotal shift, proving that collective thinking among robots could rival human teamwork in complexity and impact.

As industries stood at the cusp of broader adoption, the focus shifted to refining these systems for even greater scalability and integration with other technologies, like IoT networks. The path forward demanded continuous innovation—tweaking algorithms, expanding training simulations, and ensuring accessibility for diverse sectors. This journey, sparked by a vision of unity among machines, laid the groundwork for a future where collaborative robotics became not just a tool, but a cornerstone of progress across global landscapes.