What if a robot could fold itself into a tiny package for travel, then unfold into a fully functional machine at the push of a button, ready to tackle disaster zones or explore distant planets? This concept, once confined to the realm of science fiction, is now becoming reality thanks to groundbreaking advancements in materials science. At the forefront of this transformation are self-deploying materials, a technology that promises to reshape robotics by combining adaptability with strength in ways previously unimaginable. This innovation is not just a technical curiosity—it’s a game-changer set to impact industries from healthcare to space exploration, offering solutions to challenges that have long hindered progress.

The Power of Transformation: Why This Matters

The significance of self-deploying materials lies in their ability to address a critical gap in modern robotics: the need for structures that are both compact and robust. Traditional robots often rely on rigid components that limit portability or flexible materials that lack durability, creating a bottleneck in applications where space and strength are paramount. With this new technology, developed through cutting-edge research, the potential emerges for robots to be stored in tight spaces—like a spacecraft or an emergency kit—and then deploy with precision when needed, revolutionizing efficiency and response times.

This breakthrough is particularly timely as industries face mounting pressure to innovate. In aerospace, every ounce of weight saved translates to significant cost reductions, while in disaster response, rapid deployment can mean the difference between life and death. Self-deploying materials stand as a beacon of progress, offering a pathway to overcome these hurdles and redefine what’s possible in high-stakes environments.

A New Era of Robotics: The Context Behind the Leap

Robotics has seen remarkable strides over recent years, with soft robotics leading the charge in creating machines that mimic natural movement for use in medical devices, search-and-rescue missions, and beyond. Yet, a persistent obstacle has been finding materials that can seamlessly blend flexibility for dynamic tasks with rigidity for structural support. Conventional options often fail under stress or prove too bulky for practical use, stalling advancements in critical fields.

Enter self-deploying fiber-reinforced polymer (FRP) composites, a solution that tackles these challenges head-on. These materials align with the growing demand for lightweight, versatile tools in an age where space missions and rapid-response systems are expanding. Their development marks a pivotal moment, bridging the divide between theoretical potential and real-world application, and setting the stage for a robotics renaissance.

The Science Unveiled: How These Materials Operate

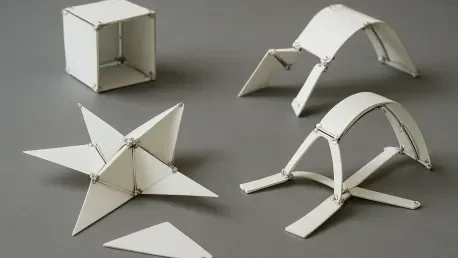

At the heart of this innovation is an origami-inspired design that allows materials to fold tightly for storage and expand with exacting accuracy when deployed. Researchers have harnessed a multi-resin fabrication process, integrating rigid and flexible epoxy resins into a single monolithic structure. This results in a material with a flexural modulus of 6.95 GPa in sturdy sections for support, and 0.66 GPa in foldable areas for adaptability, achieving a balance that traditional materials struggle to match.

Performance metrics further highlight the technology’s prowess. With a bending radius of less than 0.5 mm, the material can endure repetitive folding without cracking, even under high strain. A prototype, shaped as a triangulated cylindrical origami structure, demonstrates complex motions like bending and twisting, proving its capability for applications ranging from robotic limbs to emergency shelters, and showcasing a durability that promises long-term reliability.

The implications of this science extend across multiple domains. From aerospace components like solar sails that unfold in orbit to architectural designs for pop-up infrastructure, the lightweight yet tough nature of these composites opens up a spectrum of uses. This meticulous engineering not only solves existing material limitations but also paves the way for creative solutions in constrained environments.

Expert Perspectives: Voices Shaping the Future

Adding weight to this development are insights from key figures in the field. Associate Professor Dong Gi Seong, a leading researcher behind this technology, emphasizes its far-reaching potential, noting that it could redefine “futuristic fields of science and technology” by enabling compact, durable designs for wearable tech and satellite systems. His vision points to a world where adaptability becomes the cornerstone of innovation, transforming how challenges are approached.

Industry validation reinforces this optimism. Published findings in reputable journals underscore a consensus on the shift toward monolithic, multifunctional materials in soft robotics, highlighting their edge over segmented designs. Real-world scenarios, such as a foldable tent deploying instantly in a storm-ravaged area, illustrate the practical impact, making the abstract tangible and sparking excitement about immediate applications in critical situations.

From Lab to Life: Practical Steps for Implementation

Bringing this technology into everyday use requires strategic adoption across sectors, and actionable steps are already taking shape. In robotics, engineers are encouraged to integrate these materials into joint designs for humanoid machines, leveraging the dual-property structure to replicate fluid motion while maintaining strength. Starting with small-scale prototypes using multi-resin techniques can lay the groundwork for broader integration.

In aerospace, the focus shifts to lightweight solutions for solar panels, where tight bending radii are crucial. Testing under simulated space conditions will be key to ensuring performance, with an emphasis on durability against harsh cosmic environments. Meanwhile, emergency response teams can explore foldable shelters, initiating pilot projects in disaster-prone regions to validate rapid deployment and stability under stress, addressing urgent humanitarian needs.

Scalability remains a consideration for widespread impact. Collaboration with material scientists is essential to refine fabrication for larger or customized structures, overcoming current production constraints. These targeted approaches provide a roadmap for industries to harness the technology, ensuring that theoretical promise translates into practical transformation across diverse applications.

Reflecting on a Milestone: The Path Ahead

Looking back, the journey of self-deploying materials marked a turning point in how robotics and related fields approached design challenges. The fusion of flexibility and strength in a single structure broke barriers that once seemed insurmountable, offering a glimpse into a world where adaptability reigned supreme. This achievement stood as a testament to human ingenuity, driven by the relentless pursuit of solutions for complex problems.

The next steps call for sustained effort and collaboration. Industries are urged to invest in further testing and scaling, ensuring that innovations reach their full potential in real-world settings. Governments and organizations have the opportunity to fund pilot programs, particularly in disaster response and space exploration, to accelerate adoption. Above all, the focus remains on pushing boundaries, exploring how these materials can evolve to meet emerging needs and shape a more resilient, efficient future.