In a world where robots are increasingly tasked with delicate interactions, from surgical assistance to handling fragile objects, the challenge of replicating human-like touch remains a significant barrier, and tactile sensing—the ability to perceive and respond to physical stimuli with precision and sensitivity—has long been a bottleneck in advancing human-machine interfaces. Traditional sensors often struggle to balance softness for safe interactions with the accuracy required for detailed feedback. Enter a groundbreaking technology that promises to bridge this gap—a soft 3D lattice sensor inspired by the intricate design of human fingertips. This review explores how this innovative sensor is poised to transform robotics and beyond with its unique blend of compliance and precision.

Core Principles and Design Innovations

At the heart of this technology lies a biomimetic approach, drawing inspiration from the multilayered structure of human skin to create a sensor that mimics natural tactile perception. Developed through advanced 3D structural engineering, the soft 3D lattice sensor addresses critical limitations in conventional tactile systems, such as strain-stiffening under pressure. Its relevance spans multiple fields, including robotics, prosthetics, and wearable devices, where accurate sensory feedback is essential for seamless interaction with dynamic environments.

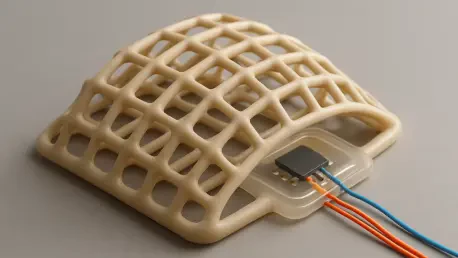

The sensor’s foundation is a hydrogel lattice crafted from a blend of PEDOT:PSS and PVA, fabricated using cutting-edge cryogenic printing techniques. This material choice ensures exceptional softness and flexibility, closely resembling the properties of human tissue. Encased within an origami-inspired framework, the design not only enhances structural integrity but also enables a controlled response to mechanical stress, setting it apart from traditional 2D sensor architectures.

Technical Features and Performance Metrics

Hydrogel Lattice and Material Advantages

A standout feature of this sensor is its hydrogel lattice, which plays a pivotal role in achieving compliance under compression. The use of PEDOT:PSS-PVA ensures that the lattice remains pliable, allowing it to deform without losing sensitivity, much like the soft tissues in a human finger. This property is crucial for applications requiring gentle contact, such as medical robotics or wearable health monitors.

Cryogenic printing, the method used to create this intricate lattice, allows for precise control over the 3D structure, ensuring consistency in performance. The resulting material can withstand repeated stress cycles while maintaining its responsiveness, a significant improvement over older hydrogel-based sensors that often hardened under pressure. This durability makes the sensor suitable for long-term use in demanding scenarios.

Origami Framework and Linear Response Mechanism

Complementing the hydrogel is an origami-inspired framework paired with metal-plate fabric electrodes, a design that facilitates a remarkable linear response across a wide pressure range of 0 to 220 kPa. This linearity, both in electrical and mechanical outputs, stems from the gradual collapse of the lattice structure during compression, which incrementally increases contact with the electrodes. Such precision is rare in soft sensors and offers unparalleled accuracy in detecting force variations.

This structural innovation ensures that the sensor can handle extreme dynamic loading without sacrificing fidelity. Unlike traditional designs that exhibit nonlinear behavior, this framework provides predictable outputs, simplifying data interpretation in complex systems. The result is a tactile sensor capable of delivering consistent feedback, whether integrated into a robotic gripper or a prosthetic limb.

Applications in Real-World Scenarios

The practical implications of this technology are vast, particularly in enhancing human-machine interactions. In robotic teleoperation, the sensor enables precise control over signal waveforms through pressure inputs, allowing operators to manipulate distant systems with exceptional accuracy. This capability is invaluable in scenarios requiring fine motor skills, such as remote surgical procedures.

Another compelling application is its use as an intelligent fingertip on robotic end-effectors. Here, the sensor excels at detecting the elastic modulus of soft tissues, providing critical data for tasks like assessing material properties or interacting with delicate objects. Its ability to adapt to varying textures and pressures enhances safety and effectiveness in contact-rich environments.

Beyond robotics, the sensor shows promise in medical diagnostics, where its sensitivity could aid in early lesion screening by detecting subtle changes in tissue stiffness. Such applications highlight its versatility, positioning it as a transformative tool across industries that demand nuanced tactile feedback for decision-making or interaction.

Challenges in Development and Scalability

Despite its impressive capabilities, the technology faces hurdles in optimizing multi-axis signal transduction. Capturing deformations across multiple directions and translating them into decoupled signals remains a complex engineering challenge. Addressing this limitation is crucial for expanding the sensor’s utility in dynamic, three-dimensional environments.

Material constraints also pose issues, as hydrogels, while soft and flexible, can be prone to degradation over time under harsh conditions. Enhancing the durability of these components without compromising their compliance is an ongoing area of research. Solutions may involve exploring hybrid materials or protective coatings to extend the sensor’s lifespan.

Scalability for mass production presents another obstacle, as the intricate fabrication process involving cryogenic printing may not yet be cost-effective on a large scale. Streamlining manufacturing techniques and ensuring consistent quality across batches are essential steps to make this technology accessible for widespread adoption in commercial applications.

Future Outlook and Emerging Trends

Looking ahead, the potential for this sensor to evolve into a multi-axis deformation detector is a promising frontier. Such advancements could enable robots and wearable systems to perceive complex physical interactions with greater detail, opening new possibilities in fields like immersive virtual reality or advanced prosthetics. Research efforts from now through 2027 are expected to focus on refining signal decoding capabilities.

Expanded applications in medical diagnostics are also on the horizon, with the sensor’s ability to detect minute variations in tissue properties potentially aiding in identifying conditions like localized scleroderma. This could revolutionize early detection methods, providing non-invasive tools for healthcare professionals to improve patient outcomes.

The broader trend in tactile sensing leans toward biomimetic 3D designs, with an increasing emphasis on integrating hybrid materials and innovative fabrication methods. As these technologies mature, they are likely to redefine sensory perception in soft robotics, paving the way for machines that interact with the world as naturally as humans do.

Final Thoughts

Reflecting on this review, the soft 3D lattice sensor stands as a remarkable leap forward in tactile sensing, blending human-inspired design with cutting-edge engineering to overcome longstanding challenges. Its ability to deliver linear responses and adapt to diverse pressures marks a turning point for robotics and human-machine interfaces. Moving forward, the focus shifts to addressing scalability and multi-axis sensing challenges through collaborative research and innovative manufacturing solutions. Exploring partnerships with industry leaders to refine production processes emerges as a critical next step. Additionally, prioritizing real-world testing in medical and industrial settings offers a pathway to validate and expand its applications, ensuring this technology reaches its full potential in transforming how machines perceive and interact with their surroundings.