Imagine a world where a robot can delicately thread its way through the intricate network of human arteries or the confined spaces of a jet engine without causing the slightest harm, a reality now being shaped by vine robots. These cutting-edge, slender, flexible machines are designed to excel in environments where traditional rigid robots simply cannot function. A transformative innovation—soft robotic skin—has recently elevated the potential of these robots, making them more adept at handling fragile and complex settings. Spearheaded by researchers under Tania K. Morimoto at the University of California San Diego, this advancement marks a significant milestone in soft robotics, promising groundbreaking applications in sensitive and constrained spaces.

The persistent challenge of maneuvering through delicate environments has long been a hurdle for roboticists, particularly when scaling down to tiny dimensions. Conventional vine robots, effective at larger sizes, often lose precision and control when reduced to mere millimeters, as their steering mechanisms become impractical. This new soft skin technology offers a revolutionary approach, paving the way for small-scale navigation that maintains both accuracy and safety in the most vulnerable of spaces.

Tackling the Barriers of Miniaturization

Addressing Traditional Constraints

The realm of robotics has often been limited by the inability of traditional vine robots to operate effectively at smaller scales, typically ranging from centimeters to meters. Mechanisms such as pneumatic actuators, motors, and tendons, while functional at larger dimensions, become inefficient or entirely unfeasible when the robot’s size is reduced to just a few millimeters. This loss of control poses significant risks in delicate environments where precision is non-negotiable. The development of a soft skin embedded with advanced materials directly confronts this issue, offering a solution that maintains maneuverability without the bulk of conventional systems. By rethinking the fundamental design, researchers have unlocked the potential for these robots to perform in spaces previously deemed inaccessible, ensuring that size no longer dictates capability.

This innovation stands as a testament to the evolving needs of industries requiring gentle interaction with fragile structures. The soft skin not only addresses the physical constraints of miniaturization but also enhances the robot’s adaptability to varied challenges. Whether it’s navigating through biological systems or industrial components, the technology ensures that even the smallest robots can execute tasks with a high degree of accuracy. This shift away from rigid, large-scale designs toward flexible, compact solutions reflects a broader movement in robotics to prioritize safety and precision in constrained environments. The implications of overcoming such size limitations are profound, opening up new possibilities for applications where traditional methods have consistently fallen short.

Redefining Precision at Millimeter Scales

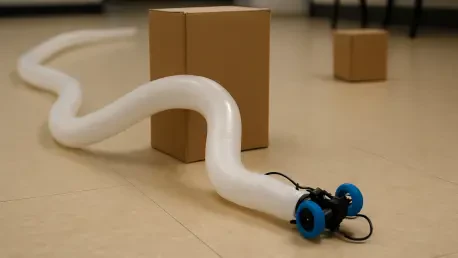

Scaling down robots to millimeter dimensions without sacrificing control has been a formidable obstacle, but the introduction of soft robotic skin changes the game entirely. Measuring just 3 to 7 millimeters in diameter, these vine robots are now equipped to handle intricate tasks that demand finesse over force. The soft skin’s design allows for seamless integration into tight spaces, ensuring that the robot can bend and twist without risking damage to its surroundings. This level of precision is critical in scenarios where even the slightest misstep could have serious consequences, such as in medical or high-stakes industrial settings. The ability to maintain such control at a reduced scale highlights a significant leap forward in robotic engineering.

Moreover, the focus on millimeter-scale navigation underscores the importance of tailoring technology to specific environmental demands. Unlike their bulkier predecessors, these robots can slip through gaps as narrow as half their diameter, a feat that showcases their unparalleled adaptability. This precision is not just about size but about redefining how robots interact with the world around them, prioritizing gentle movements over aggressive force. The result is a tool that can be trusted in the most sensitive of contexts, from exploring human anatomy to inspecting critical machinery. As this technology continues to evolve, it sets a new standard for what small-scale robotics can achieve, proving that even the tiniest machines can make a massive impact.

Breakthroughs in Robotic Design and Functionality

Harnessing Liquid Crystal Elastomer Actuators

Central to the success of these vine robots is the integration of liquid crystal elastomer (LCE) actuators within a soft robotic skin, a design choice that balances strength with flexibility. These actuators are remarkably thin, allowing the robot to remain lightweight while still possessing the durability needed for complex movements. Their unique properties enable the robot to adapt to varying conditions without losing structural integrity, a crucial factor when operating in fragile environments. This material innovation ensures that the robot can perform intricate maneuvers at a scale previously thought impossible, marking a significant advancement in the field of soft robotics. The use of LCE actuators represents a thoughtful approach to addressing the challenges of small-scale design.

Beyond the material itself, the implementation of LCE actuators highlights a deeper understanding of how robots must evolve to meet modern demands. The soft skin’s ability to conform to tight spaces while maintaining control is a direct result of this cutting-edge technology, which prioritizes adaptability over rigidity. This approach not only enhances the robot’s functionality but also reduces the risk of damage to delicate surroundings, a critical consideration in high-stakes applications. Whether navigating biological pathways or industrial interiors, the actuators provide a level of precision that sets these robots apart from traditional models. As research progresses, the potential for refining and expanding the use of such materials in robotics promises even greater strides in capability and safety.

Mastering Dual Control Systems

Another key aspect of this technological breakthrough is the dual control mechanism that enhances the robot’s steering capabilities through a combination of internal pressure adjustments and temperature regulation. Embedded flexible heaters allow for precise thermal control of the LCE actuators, while pressure modifications fine-tune the robot’s movements. This synergy offers a level of maneuverability far superior to single-method systems, enabling the robot to navigate complex paths with remarkable accuracy. The ability to adjust both factors simultaneously ensures that the robot can respond dynamically to changing environments, a feature that is essential for operating in unpredictable or confined spaces. This dual approach redefines how control is achieved in small-scale robotics.

The significance of this control system extends beyond mere functionality to the very nature of robotic interaction with fragile settings. By allowing for sharper turns—exceeding 100 degrees along the robot’s length—and passage through incredibly narrow gaps, the technology demonstrates an unprecedented level of responsiveness. This is particularly vital in contexts where every movement must be calculated to avoid disruption or damage, such as in medical or precision engineering tasks. The dual control mechanism also paves the way for future innovations, as researchers explore ways to further optimize these systems for even greater efficiency. As a result, this advancement not only addresses current limitations but also sets the stage for more sophisticated robotic behaviors in the years ahead.

Practical Applications and Future Horizons

Demonstrating Capability in Sensitive Settings

The practical utility of vine robots equipped with soft skin technology has been vividly demonstrated through rigorous testing in simulated environments that mirror real-world challenges. In models replicating human arteries, the robots showcased their ability to navigate intricate pathways with sharp turns and minimal disruption, proving their potential for medical applications. Similarly, within the confined interiors of jet engine replicas, they maneuvered through tight spaces while carrying tiny cameras for detailed inspections. These tests affirm the robots’ capacity to operate in fragile settings where precision and care are paramount, highlighting their value in both healthcare and industrial maintenance. The results underscore the transformative impact of this technology on tasks requiring a gentle touch.

Equally impressive is the robot’s ability to adapt to the unique demands of each environment, a testament to the versatility of the soft skin design. The capability to squeeze through openings as small as half their diameter without compromising performance speaks to the meticulous engineering behind these machines. This adaptability ensures that they can handle a wide range of scenarios, from non-invasive medical procedures to critical equipment checks, without risking damage to the surrounding structures. Such demonstrations not only validate the current technology but also build confidence in its potential to address pressing needs across multiple fields. As these robots prove their worth in controlled settings, the path toward real-world implementation becomes increasingly clear, promising significant advancements in operational safety and efficiency.

Expanding the Scope of Soft Robotics

Looking beyond their immediate applications, the soft skin technology developed for vine robots holds immense promise for a broader array of soft robotic systems. Imagine wearable haptic devices that provide tactile feedback with unparalleled sensitivity or soft grippers capable of handling the most delicate objects without causing harm. The adaptability of this technology suggests it could revolutionize various sectors, from assistive medical tools to precision manufacturing, by offering solutions that prioritize flexibility and gentleness. This potential for cross-application innovation indicates that the impact of soft skin technology may extend far beyond its current use, reshaping how robots interact with the world in diverse contexts. The horizon for such advancements appears both vast and exciting.

Furthermore, the vision for expanding this technology includes ambitious goals such as integrating remote or autonomous control, which could further enhance its utility in inaccessible or hazardous environments. Plans to push the boundaries of miniaturization also signal a future where even smaller robots could tackle increasingly complex tasks with ease. These aspirations reflect a commitment to continuous improvement, ensuring that the technology evolves to meet emerging challenges. By laying the groundwork for such developments, the research team is not only addressing current limitations but also anticipating future needs, fostering a new era of robotic versatility. The broader implications of these efforts suggest a transformative shift in how soft robotics can contribute to innovation across industries, setting a precedent for adaptable and safe technological solutions.

Reflecting on a Groundbreaking Milestone

A Step Forward in Robotic Evolution

Looking back, the introduction of soft skin technology for vine robots marked a pivotal moment in the journey of robotics, particularly in navigating fragile and complex environments. The successful integration of liquid crystal elastomer actuators into a flexible design addressed long-standing challenges of small-scale control, allowing robots to operate at millimeter dimensions with remarkable precision. This achievement stood out as a clear departure from the limitations of rigid, traditional systems, proving that adaptability could coexist with strength. The ability to maneuver through simulated human arteries and jet engine interiors without causing harm highlighted a profound shift toward safer, more effective tools. This milestone redefined expectations for what robots could accomplish in sensitive settings.

Charting the Path Ahead

Reflecting on this innovation, it’s evident that the groundwork laid by the soft skin technology opened doors to actionable next steps for the field. The demonstrated potential in medical and industrial applications underscored the need for continued investment in refining control systems and exploring autonomous operations. Further miniaturization efforts promised to expand the reach of these robots into even tighter spaces, while adapting the technology for other soft robotic systems hinted at broader utility. The focus shifted toward bridging the gap between controlled testing and real-world deployment, ensuring that such tools could reliably address practical challenges. This forward-looking approach not only celebrated past successes but also prioritized sustainable advancements, guiding robotics toward a future of greater precision and safety in delicate environments.