As industrial automation rapidly evolves from a futuristic concept into a daily operational reality, the demand for engineers skilled in managing complex robotic systems has surged, creating a significant gap between traditional academic curricula and the practical needs of the modern workforce. The key to bridging this divide lies in immersive, hands-on educational experiences that precisely replicate the sophisticated, multi-faceted environments students will encounter in their careers. To this end, strategic partnerships between academia and industry leaders are proving essential, facilitating the development of advanced training facilities within universities. A recent educational grant awarded by the DENSO North America Foundation to Kettering University, totaling $155,000, exemplifies this trend. This funding is dedicated to expanding an existing industrial robotic cell, ensuring that engineering students gain practical expertise in automation, robotics, and advanced manufacturing, thereby preparing them for the immediate challenges and expectations of the technology-driven industrial landscape.

Bridging the Gap Between Theory and Application

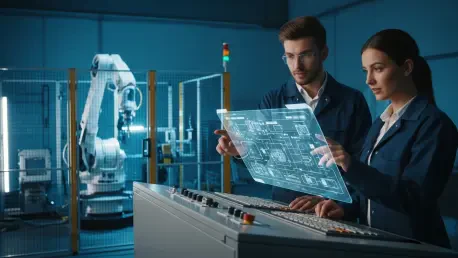

The transition from theoretical knowledge to practical application represents a fundamental challenge in engineering education, particularly in fields as dynamic as robotics and automation. While classroom instruction provides a crucial foundation in principles like programming, kinematics, and control systems, it often falls short of preparing students for the intricate realities of a modern factory floor. Working with isolated pieces of equipment in a controlled lab setting does not adequately convey the complexity of integrated systems, where multiple robots, sensors, and data streams must operate in seamless coordination. Dr. Scott Grasman, who oversees engineering programs at Kettering, emphasizes that this expansion is vital for aligning student competencies with the rapidly advancing technological landscape. The enhanced learning environment moves beyond single-robot exercises, compelling students to engage with the kind of interconnected, multi-robot ecosystems that are now standard in the automotive and industrial automation sectors, fostering applied problem-solving skills in a highly realistic context.

This forward-thinking educational model is designed to cultivate a deep, holistic understanding of modern manufacturing by integrating a wide array of critical disciplines into a single, cohesive learning experience. The curriculum extends far beyond basic robotic operation to include sophisticated topics such as automation workflow design, complex system integration, and advanced industrial programming languages. Students are challenged to not only make the robots function but also to optimize their performance through data-driven automation, ensuring system reliability and efficiency. Moreover, the program instills a crucial awareness of cybersecurity protocols necessary to protect interconnected industrial networks from potential threats. It also highlights the importance of human oversight in creating transparent and dependable manufacturing systems. By immersing students in these multifaceted challenges, the initiative prepares a new generation of engineers who are not just technically proficient but are also equipped to design, manage, and secure the intelligent factories of today and tomorrow.

Fostering a Culture of Safety and Trust

A paramount aspect of preparing students for careers in industrial automation is instilling a profound understanding of and respect for the stringent safety protocols that govern real-world production environments. While hands-on experimentation is encouraged, the core safety systems of the training cell are intentionally locked and inaccessible to students. This critical design choice reinforces the non-negotiable nature of safety interlocks and emergency protocols in an operational setting. Students are free to test, debug, and modify programming code to observe different outcomes and learn from their mistakes, but they must do so within a framework that prioritizes safety above all else. This approach teaches them a vital lesson: innovation and creativity in automation must always coexist with rigorous safeguards. By operating within these realistic constraints, students learn to appreciate how intelligent manufacturing technologies are designed, validated, and implemented in a manner that builds and maintains trust between human operators and their robotic counterparts.

The successful integration of automation in any industrial setting hinges on the trust that human workers place in the robotic systems they operate alongside. This trust is not built merely on efficiency or productivity metrics but is forged through consistent, reliable, and safe operation. The educational experience within the advanced robotic cell is structured to demonstrate how this trust is systematically established. Students learn that every line of code and every mechanical adjustment has implications not only for the task at hand but also for the overall safety and integrity of the manufacturing process. This deep-seated understanding of the relationship between programming, hardware, and safety protocols is indispensable. It ensures that future engineers enter the workforce with a mindset that prioritizes the creation of dependable, transparent, and secure automated systems, ultimately fostering a collaborative environment where humans and machines can work together effectively and safely to achieve production goals.

A Blueprint for Future Engineering Education

The collaboration that led to this enhanced training facility provided a model for how educational institutions can effectively prepare students for the demands of Industry 4.0. The initial development of the robotic cell, a joint effort with industry experts from Patti Engineering and Mitsubishi Electric, laid the groundwork for an authentic learning environment. The subsequent funding from the DENSO North America Foundation, part of its 2026 education grant program that allocated nearly $1 million across five universities, amplified this effort. This investment not only expanded the physical capabilities of the cell but also extended its instructional value for future cohorts of engineering students. It underscored a shared recognition that cultivating a skilled workforce in science, technology, engineering, and mathematics (STEM) is a collective responsibility. Such initiatives demonstrated how targeted corporate philanthropy, when aligned with academic vision, could create powerful, lasting impacts on both student development and the long-term health of the manufacturing sector.