Horizon GmbH is at the forefront of revolutionizing the manufacturing industry through its strategic adoption of smart technology. Under the innovative leadership of Timm Edelhoff, Horizon is leveraging advanced technologies like AI, automation, and robotics to enhance operational efficiency, productivity, and customer satisfaction. This article will explore Horizon’s approach to smart manufacturing and the broader trends shaping the industry’s future.

Pragmatic Approach to Automation

Customer-Centric Technology Adoption

Horizon GmbH’s commitment to automation goes beyond the mere incorporation of new technologies. Timm Edelhoff emphasizes that each technological innovation must serve a practical purpose, primarily benefitting customers while ensuring a solid return on investment (ROI). Implementing technology without an evident benefit to the customer or the bottom line is considered wasteful and ineffective. Horizon’s strategy revolves around this pragmatic approach, guiding the deployment of advanced systems that solve specific challenges faced by the company, such as their AI-integrated ERP system designed to streamline warehouse operations.Horizon GmbH’s practical application of automation is most evident in its AI-based ERP system for warehouse management. This innovative tool allows for real-time tracking and inventory management, ensuring that all components are available exactly when and where they are needed. By optimizing logistics, Horizon reduces downtime and increases production throughput, directly addressing customer demands for timely delivery and high-quality products. This cautious yet effective approach to technology adoption exemplifies the company’s commitment to blending innovation with practicality, ensuring that each technological advancement leads to measurable improvements in business operations.

AI-Enhanced Administrative Efficiency

Incorporating AI into the core operations of Horizon GmbH, the company has streamlined numerous administrative tasks and improved customer interactions. AI systems integrated with the ERP system ensure precise delivery of parts in terms of time, location, and specifications. This AI-driven approach enhances the accuracy and efficiency of the company’s supply chain, allowing for better resource management and quicker response times to customer needs. By leveraging AI, Horizon ensures that administrative tasks, from order processing to inventory control, are executed with unmatched precision and speed.Moreover, AI’s role extends into customer relationship management (CRM) as well, fostering a higher level of service quality. The AI systems used by Horizon can analyze vast amounts of customer data to predict needs and preferences, enabling personalized interactions and solutions. This not only boosts customer satisfaction but also enhances the company’s ability to retain clients and attract new business. The synergy between AI and human expertise in administration solidifies Horizon GmbH’s standing as a forward-thinking, customer-centric organization that employs technology to enhance service delivery and operational efficiency.

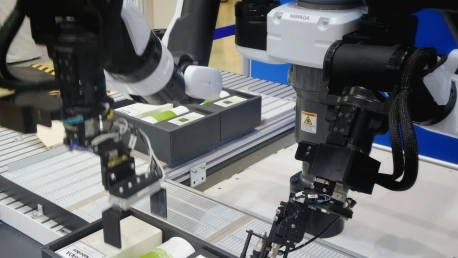

Implementing Robotics for Operational Efficiency

Self-Driving Robots

Horizon GmbH has taken significant strides in automating routine tasks by deploying self-driving cleaning robots across its showrooms and factories. These autonomous systems handle cleaning, reducing operational costs and enabling personnel to focus on more critical and complex tasks. The introduction of self-driving robots aligns with Horizon’s broader strategy to harness automation for boosting efficiency. By eliminating labor-intensive, repetitive tasks, the company reallocates human resources to areas where they can add the most value.The employment of self-driving robots demonstrates Horizon’s commitment to leveraging innovative solutions for task automation. These robots, outfitted with state-of-the-art navigation and cleaning technologies, ensure that workspaces remain immaculate without requiring continuous human oversight. This consistent level of cleanliness not only improves the working environment but also contributes to higher overall plant productivity. Autonomous robots are a testament to Horizon’s innovative use of technology to enhance everyday business operations, reflecting a forward-looking vision that balances technological investment with tangible operational benefits.

Role of Robotics in Labor Reallocation

Robotics not only serves in operational capacities but also plays a crucial role in reassigning human labor. By automating repetitive tasks, Horizon ensures that its workforce can engage in more value-added activities such as innovation, quality control, and customer service. This reallocation leads to a more motivated and productive workforce, essential for fostering long-term growth and sustainability in the competitive manufacturing sector. The strategic use of robots for mundane tasks allows employees to focus on roles that require human ingenuity and problem-solving skills, driving innovation and continuous improvement.The integration of robotics extends beyond simple task automation. Horizon’s workforce benefits from enhanced training and development opportunities as they transition into more complex roles that leverage their skills and talents. This symbiotic relationship between human and robotic labor not only increases efficiency but also enriches the work life of employees, making Horizon an employer of choice within the industry. By redefining the roles of human workers through the adoption of robotics, Horizon GmbH not only boosts operational efficiency but also fosters a culture of continuous learning and professional development.

The Advanced Horizon BQ-500 Perfect Binder

Features and Capabilities

One of Horizon GmbH’s flagship innovations is the Horizon BQ-500 perfect binder. This state-of-the-art machine features a cloud-based iCE LINK workflow and job-management tool, 21 automated sections, advanced visual monitoring, and the capability to handle variable production at high speeds. The BQ-500 is heralded as the most productive in its class for book-of-one production, representing a significant leap in manufacturing technology. Its sophisticated design and functionality epitomize Horizon’s commitment to combining cutting-edge technology with practical applications to meet customer needs.The Horizon BQ-500 perfect binder is a symbol of the company’s advancement in manufacturing capabilities. The machine’s 21 automated sections reduce manual interventions, ensuring consistent quality and precision in the binding process. The cloud-based iCE LINK system enhances job management, offering real-time monitoring and adjustments to maintain optimal performance. This combination of automation and cloud technology allows Horizon to meet diverse customer requirements efficiently, making the BQ-500 a cornerstone of their operation.

Impact on Productivity

The deployment of the Horizon BQ-500 perfect binder illustrates the company’s commitment to pushing the boundaries of automation. By incorporating advanced technologies like cloud-based management and extensive automation, the BQ-500 substantially boosts productivity and operational efficiency. These improvements translate directly into enhanced customer satisfaction and substantial ROI, reinforcing Horizon’s position as a leader in smart manufacturing. The BQ-500 has set new production benchmarks, demonstrating Horizon’s ability to integrate sophisticated technology into their manufacturing processes seamlessly.The impact of the BQ-500 extends beyond productivity gains. By automating complex binding tasks, the machine ensures that production schedules are met without compromising on quality. This reliability is crucial for maintaining customer trust and ensuring repeat business. Additionally, the BQ-500’s capabilities free up human operators to focus on critical tasks such as oversight and quality assurance, enhancing overall workforce efficiency. The strategic deployment of the BQ-500 is a clear indication of Horizon’s forward-thinking approach to technology, which prioritizes both innovation and practical application for maximum operational benefit.

Broader Industry Adoption by SMEs

Trends in Small to Medium-Sized Enterprises

Horizon GmbH’s adoption of smart factory technologies mirrors a broader trend within the manufacturing industry, especially among small to medium-sized enterprises (SMEs). More SMEs are recognizing the potential benefits of integrating advanced technologies into their operations. By embracing automation, AI, and robotics, these companies aim to achieve significant improvements in efficiency and productivity. The success stories of companies like Horizon serve as a model for other SMEs, showcasing the tangible benefits of adopting smart technologies.This industry-wide shift towards smart technology adoption highlights the growing need for efficiency and competitiveness in the manufacturing sector. SMEs, in particular, stand to gain substantially from this transition, as these technologies can level the playing field against larger competitors. By investing in smart technologies, SMEs can optimize their processes, reduce costs, and improve product quality, making them more agile and responsive to market changes. This trend signifies a broader recognition within the industry that automation and advanced technologies are not just beneficial but essential for long-term sustainability and growth.

Benefits of Smart Technology for SMEs

For SMEs, the transition to smart technology presents a unique opportunity to compete with larger enterprises. The implementation of robust, automated systems contributes to reducing operational costs, optimizing workflows, and increasing output quality. Consequently, SMEs that adopt smart factory principles are better positioned to meet customer demands and scale their businesses effectively. Following Horizon GmbH’s example, more SMEs are investing in AI, automation, and robotics to enhance their operational capabilities and market position.The adoption of smart technologies offers SMEs numerous advantages beyond operational efficiency. These technologies enable better data collection and analysis, providing valuable insights into production processes and customer preferences. SMEs can leverage this data to make informed decisions, refine their strategies, and innovate continuously. Moreover, the implementation of automation and AI can alleviate some of the labor shortages faced by SMEs, allowing them to maintain high productivity levels with a smaller workforce. Overall, the adoption of smart technologies equips SMEs with the tools they need to thrive in a competitive landscape, driving industry-wide advancements.

Vision for the Future: Dark Factories

Concept of Dark Factories

Looking towards the future, Timm Edelhoff envisions ‘dark factories,’ fully automated manufacturing facilities operating without human intervention. These factories rely entirely on advanced robotics, AI, and IoT systems to function. The concept of dark factories represents the pinnacle of Horizon’s vision for smart manufacturing, where human labor is minimized to maximize efficiency and productivity. This futuristic model of manufacturing is designed to operate flawlessly around the clock, producing high-quality outputs consistently without the need for human oversight.The idea of dark factories marks a revolutionary shift in the manufacturing paradigm, driven by the relentless pursuit of optimization and efficiency. Such fully automated setups could redefine production processes, minimizing errors and waste while maximizing output. The concept highlights Horizon’s commitment to staying ahead of technological trends, ready to implement cutting-edge solutions that push the envelope of what’s possible in manufacturing. A transition towards dark factories could transform the industry, setting new standards for operational excellence, cost-efficiency, and scalability.

Implications for Manufacturing

Horizon GmbH is pioneering the transformation of the manufacturing industry by strategically integrating smart technology. Under the visionary direction of Timm Edelhoff, the company is capitalizing on cutting-edge advancements such as artificial intelligence, automation, and robotics. These technological innovations are key to boosting operational efficiency, enhancing productivity, and improving customer satisfaction.This article delves into Horizon’s smart manufacturing strategy, examining how the company employs AI and robotics to streamline processes while reducing costs. It also discusses the broader industry trends that are influencing the future of manufacturing. Key elements include the increasing shift towards digitalization, the importance of data analytics in making informed decisions, and the role of automation in maintaining competitive advantage.By embracing these technologies, Horizon is not only optimizing its production lines but also setting a new standard for modern manufacturing. The company’s approach exemplifies how smart technology can be effectively harnessed to drive growth and efficiency in a rapidly evolving landscape.