The emergence of humanoid robots is poised to revolutionize the landscape of industrial automation in ways that few could have imagined even a decade ago. As these advanced machines become more capable and versatile, they present both remarkable opportunities and significant challenges for the future of industrial robotic arms. This article delves into the potential impact of humanoid robots on the evolution of industrial robotic arms, exploring their historical development, current advancements, and future prospects. By examining the interplay between humanoids and traditional robotic arms, we can gain a better understanding of how industrial automation is likely to evolve in the coming years and identify the key factors that will shape its trajectory.

The Evolution of Industrial Robotic Arms

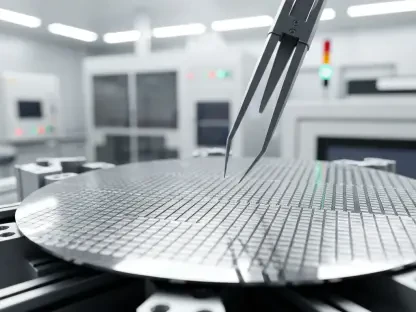

The journey of industrial robotic arms began in the 1950s with the invention of the Unimate by George Devol and Joseph Engelberger. This pioneering robot, installed at General Motors in 1961, performed repetitive and hazardous tasks such as die casting and welding. Although rudimentary compared to modern technology, the Unimate’s programmable nature was revolutionary, laying the foundation for rapid advancements in industrial automation. Over the next two decades, the use of robotic arms gained traction, particularly in the automotive sector where scalable and consistent production was crucial.

Throughout the 1970s and 1980s, significant improvements in robotic arm technology were made. Companies like Fanuc and Kuka led the charge, producing robots with enhanced precision and reliability. Advances in materials and control systems allowed these robots to handle delicate tasks like assembly and painting. The introduction of computer numerical control (CNC) in the 1980s enabled seamless integration with computerized production lines, further expanding the use of robotic arms across various industries. By the end of the 20th century, robotic arms had become an indispensable part of manufacturing processes worldwide, offering unprecedented levels of efficiency and consistency.

The Rise of Collaborative Robots (Cobots)

In the 1990s, industrial robotic arms became more versatile, finding applications in diverse sectors such as pharmaceuticals, aerospace, and food production. Advanced sensors and real-time control systems were integrated, enhancing their safety and efficiency. By the 2010s, collaborative robots, or cobots, emerged as a significant advancement. Companies like Universal Robots developed cobots that could work alongside humans without extensive safety barriers. This radical shift opened new possibilities for automation, particularly for small and medium-sized enterprises.

Cobots featured force-limiting sensors, allowing them to stop immediately if they came into contact with a human. This innovation made automation accessible to smaller businesses and changed the perception of robots as inherently hazardous. Cobots have since dominated the market, with traditional robotic arms incorporating features inspired by cobots to enhance safety and usability. The adoption of cobots has allowed for a more flexible and integrated working environment where humans and robots can collaborate seamlessly on various tasks ranging from assembly to quality control.

The Advent of Humanoid Robots

Humanoid robots, developed by companies like Tesla, Figure AI, and Boston Dynamics, are capable of performing tasks traditionally executed by robotic arms, such as welding, assembly, and inspection. These robots offer several noteworthy advantages over traditional robotic arms, including adaptability, dexterity, and potential cost-effectiveness. The human-like form of humanoid robots allows them to operate in environments designed for human workers, thereby reducing the need for custom infrastructure and retrofitting existing facilities.

Their dexterity enables them to perform tasks requiring fine motor skills and access tight spaces that are challenging for traditional robotic arms. While currently expensive, advancements in mass production could make humanoid robots more affordable in the long term. As technology continues to advance, the potential for humanoid robots to replace or supplement traditional robotic arms in various industrial applications becomes increasingly feasible. This shift has the potential to redefine the landscape of industrial automation, pushing the boundaries of what is possible in manufacturing and production processes.

Market Growth and Regional Trends

Since the 1950s, the market for industrial robotic arms has grown exponentially. The International Federation of Robotics (IFR) reported that the number of industrial robots in operation worldwide surpassed 3.5 million in 2022. This growth has been driven by rising labor costs, the need for increased productivity, and technological advancements. Asia, particularly China, has emerged as the largest market, with over 50% of global robot installations. This region’s evolving industrial landscape and investment in automation have propelled it to the forefront of robotic adoption.

Europe and North America follow with significant investments in automation across various sectors, including automotive, electronics, and logistics. As robots become more intelligent, adaptive, and sustainable, their role in industrial automation will continue to evolve. The continuous upward trajectory of robot integration into manufacturing serves as a testament to the indispensable nature of these machines in modern industry. Regional trends indicate that despite economic fluctuations, the demand for automation remains robust, driven by both economic necessity and technological innovation.

Advancements in Artificial Intelligence and Machine Vision

The past five years have witnessed an explosion in the capabilities of robotic arms, driven by advancements in artificial intelligence (AI) and machine vision. These technologies have enabled robots to perform complex tasks with greater autonomy and precision, including quality inspection, material handling, and the assembly of intricate components. Artificial intelligence and machine vision allow robots to learn new tasks without extensive reprogramming, making them more adaptable to changing production needs.

Modular designs may facilitate customization for specific applications, while advancements in materials could reduce size and weight. Sustainability is becoming increasingly important, with manufacturers seeking energy-efficient robots to minimize environmental impact. As AI continues to evolve, the potential for more intelligent and intuitive robotic systems grows, paving the way for unprecedented levels of efficiency and productivity in various industrial applications. This continuous innovation is set to redefine the capabilities of robotic arms, making them even more critical assets in the manufacturing process.

The Challenge of Integrating Humanoids and Robotic Arms

The rise of humanoid robots is set to transform the field of industrial automation in unimaginable ways compared to a decade ago. These sophisticated machines are becoming increasingly capable and versatile, presenting both incredible opportunities and notable challenges for the future of industrial robotic arms. This article explores the potential impact of humanoid robots on the progression of industrial robotic arms, looking at their historical development, current advancements, and future possibilities. By analyzing the dynamic relationship between humanoid robots and traditional robotic arms, we can better understand how industrial automation is likely to evolve moving forward. Additionally, we can identify the crucial factors that will influence its direction. As these robots become more integrated into various sectors, they will likely change how industries operate, improve efficiencies, and redefine job roles. Thus, gaining insight into this evolution will be critical for industries to adapt and leverage these technological advancements effectively.