I’m thrilled to sit down with Oscar Vail, a technology expert whose deep knowledge of cutting-edge fields like quantum computing, robotics, and open-source projects has positioned him as a thought leader in the industry. With a keen eye on how tech transforms operations, Oscar brings a unique perspective to the world of e-commerce logistics and data analytics. Today, we’ll dive into the inner workings of modern e-commerce warehouses, exploring how data-driven strategies and innovative technologies are revolutionizing the way brands keep up with skyrocketing customer expectations. We’ll touch on the critical role of analytics in streamlining operations, the impact of automation, and the challenges of managing complex warehouse processes in a fast-paced online shopping landscape.

How do e-commerce warehouses differ from traditional warehouses, and what makes them so vital to today’s online shopping world?

E-commerce warehouses are a whole different beast compared to traditional ones. Traditional warehouses were essentially big storage sheds—products sat on shelves for weeks or months until a truck came to pick them up. It was slow, steady, and focused on bulk. E-commerce warehouses, on the other hand, are built for speed and agility. Orders come in by the thousands every hour, and items need to be pulled, packed, and shipped out almost instantly to meet customer demands for next-day or even same-day delivery. They’re vital because they’re the backbone of the online shopping experience. Without them, the promise of fast, reliable delivery falls apart. Mess up an order, and you’ve got unhappy customers and bad reviews. Get it right, and you build trust and loyalty that keeps people coming back.

What role has the explosion of online shopping played in reshaping day-to-day warehouse operations?

The growth of online shopping has turned warehouses into high-pressure environments. We’re talking about global e-commerce sales projected to hit $7 trillion in the coming years—that’s a tidal wave of demand. Day-to-day operations have had to adapt to handle constant order flows, tighter delivery windows, and higher customer expectations like free shipping or perfect packaging. Warehouses now rely on real-time tracking and data to manage inventory, assign tasks, and avoid delays. It’s no longer just about storing goods; it’s about orchestrating a complex dance of receiving, picking, packing, and shipping, often under intense time constraints like holiday surges or flash sales.

How has data analytics transformed the management of e-commerce warehouses in recent years?

Data analytics has been a game-changer. It’s shifted warehouse management from guesswork to precision. A few years ago, managers might’ve relied on gut feelings to stock inventory or schedule staff. Now, they’ve got tools that analyze historical sales, predict demand, and even optimize labor schedules. For instance, analytics can pinpoint slow spots in the picking process or forecast holiday spikes, allowing warehouses to prepare in advance. It’s also about cost-cutting—reducing overstock, minimizing waste, and improving energy use. With 32% of businesses already having a data strategy, as some reports suggest, it’s clear that analytics isn’t just a trend; it’s becoming the standard for staying competitive.

Can you share a specific example where data analytics solved a real problem in a warehouse setting?

Absolutely. I’ve seen a mid-sized warehouse struggling with shipping delays during peak seasons like Black Friday. Orders were piling up, and customers were getting frustrated. By implementing a predictive analytics tool, they started analyzing past order patterns and local delivery bottlenecks. The system flagged high-demand products and suggested pre-positioning them closer to packing stations. They also adjusted staffing based on predicted order volumes. The result? Delivery times dropped by nearly 30% during the next holiday rush, and customer complaints plummeted. It showed me how data can turn chaos into control.

What types of technology are most critical to keeping a modern e-commerce warehouse running smoothly?

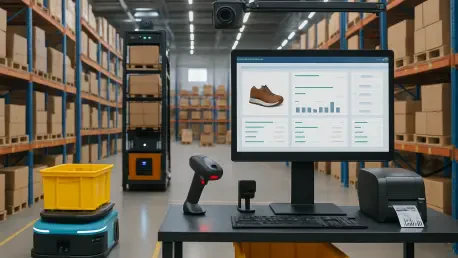

There’s a whole tech ecosystem at play. Warehouse Management Systems, or WMS, are the brains of the operation—tracking inventory, assigning tasks, and ensuring nothing slips through the cracks. Barcode scanners and RFID tags are crucial for accuracy; every scan confirms the right item is in the right place. Then you’ve got automation—robots and conveyor systems that move goods with precision, cutting down on human error and physical strain. Data analytics ties it all together, giving managers an x-ray view of operations to spot inefficiencies. Without this tech, modern warehouses couldn’t keep up with the pace of e-commerce.

How do you see automation and robotics impacting the workforce in these warehouses?

Automation and robotics are often misunderstood. They’re not about replacing workers; they’re about enhancing them. Robots handle repetitive, heavy tasks like moving pallets or sorting boxes, which frees up human workers to focus on more complex roles like problem-solving or quality checks. I’ve seen setups where robots zip through aisles fetching items, while workers oversee the process and handle exceptions. It’s a partnership. That said, there’s a learning curve—staff need training to work alongside these systems. And while labor shortages are a real issue, automation helps fill gaps without fully sidelining the human element.

What are some of the biggest operational challenges in e-commerce warehouses, and how can they be addressed?

One major headache is inventory accuracy. Telling a customer you’ve got a product in stock, only to realize it’s missing, kills trust fast. Then there’s holiday surges—think Black Friday—where order volumes can turn a calm warehouse into chaos. Returns are another drain; they take time and resources to process. Labor shortages also hit hard; finding reliable staff isn’t easy. Solutions often come down to smarter layouts, like placing high-demand items near packing areas, and investing in tech like a robust WMS to streamline tasks. Training is huge—well-trained staff work faster and make fewer mistakes. Some companies even outsource to fulfillment specialists to offload the stress.

What’s your forecast for the future of data analytics and technology in e-commerce warehouses?

I’m really excited about where this is headed. I think we’ll see data analytics get even smarter with AI, predicting customer orders before they’re placed by analyzing browsing habits and trends. Imagine a warehouse that stocks up on trending items before the demand spike hits. Automation will keep evolving—think more autonomous robots and IoT devices tracking every move in real time. There’s also a push toward sustainability, with analytics optimizing energy use and reducing waste through eco-friendly practices like biodegradable packing. As e-commerce grows, I believe warehouses will look less like dusty storage spaces and more like sleek tech hubs, driven by data and innovation.