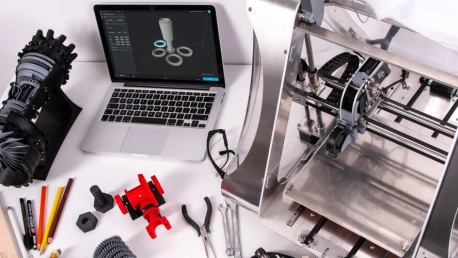

3D printing is a technology that has developed rapidly in recent years. It involves creating physical objects from digital model file formats such as Stereolithography (STL) and Virtual Reality Modeling Language (VRML). Currently, 3D printing is used primarily in the design of consumer products, medical modeling, prototyping, and the creation of low-cost replicas of high-tech products. As this technology continues to evolve, more creative uses will likely be found in the coming years.

Read this article to learn more about some potential future uses of 3D printing, and how it could change the way products are manufactured and marketed.

Medical Industry and Healthcare

Healthcare is one industry where 3D printing is having a long-term impact. Not only is it changing the way medical devices are made, but it is also helping to improve the quality of patient care. With the introduction of this technology into the medical field, doctors and other medical professionals can provide more affordable and effective medical services to their patients. Currently, medical 3D printing is being used to create prosthetic limbs, bone, and joint reconstruction, and even bioprinting artificial organs and tissues. Patients no longer have to be placed on long transplant lists and receive delayed treatment. Researchers are even working on 3D printing the human heart from patient cells.

In the future, 3D printers could also be used to create new body parts from scratch—something that is currently impossible due to the complexity and rarity of human organs and tissue samples needed for research purposes. Another use case for 3D printers in the healthcare industry is the creation of complex biomedical structures that can be used in the development of bone and tissue reconstruction technologies.

Dentists are also increasingly using 3D printing to provide patients with 3D models of tooth restoration to help them visualize the potential outcome before surgery. 3D printing can also provide dentists with realistic models of teeth that have been damaged beyond repair. This allows them to make more accurate decisions about whether to perform reconstructive surgery.

Business and Manufacturing Industry

3D printing has proven to be extremely useful in the manufacturing industry. It aids in the production of a wide range of objects from a variety of materials, without the need for specialized equipment or training. This technological breakthrough has transformed the manufacturing process, allowing businesses to produce goods faster and at a lower cost than ever before. Manufacturers can now use additive manufacturing (AM) or additive layer manufacturing (ALM), a process that requires computer-aided design (CAD) software and a 3D printer to create objects from a digital model. Besides plastic, other materials used in additive manufacturing include metal and even ceramics.

The biggest advantage of using 3D printing in manufacturing is that it is environmentally friendly, produces fewer harmful byproducts, and consumes less energy than a traditional factory. In addition, manufacturers don’t have to hire unwanted labor and can keep their production lines running 24×7. It is also an affordable technology that allows businesses to produce more customized items and prototypes. The design process can be more innovative and creative when there is more room for experimentation. Currently, there is no practical limit to the size of an object that can be printed using this technology. Anything from car parts to a single screw can potentially be 3D printed.

Aerospace Industry

There is a growing trend toward 3D printing in the aerospace industry. Many airlines are exploring ways to print parts and components using additive manufacturing techniques. This could provide several benefits, including reducing waste and increasing efficiency. It could also make it possible to produce custom parts that are not commercially available, such as:

- Custom seats for passengers;

- New airplane components (like wings, fuselage sections, and landing gear);

- Replacement parts (for engines, helicopters, etc.)

One major advantage that 3D-printed parts have over traditional elements is that they can be made using less material and with lighter weight, which could lead to a significant reduction in fuel consumption. Production costs could also be reduced, as 3D printing techniques are often more affordable than traditional manufacturing methods. This, in turn, makes flying more economical for customers. Aside from producing and replacing broken parts, this technology has various applications in the aviation sector. For example, airlines are using 3D printing technology to create prototypes of new aircraft designs. This ensures the designs work as intended before investing money in manufacturing a full-scale version of an aircraft.

Automotive Industry

The automotive industry is experiencing a boom in the use of 3D printing. This technology is being used to produce parts for cars that were previously impossible or very expensive to produce. 3D printing can eliminate many of the steps and time wasted during manufacturing processes. It can also be used to make custom parts just for a particular car model or series, which decreases production costs and increases efficiency.

Moreover, 3D printers are versatile machines that allow for the production of different types of materials. This makes them ideal for manufacturing complex components like engines or gears—something that would be impossible using traditional methods. Since 3D printing can build fully functional cars from start to finish without scrapping any parts, manufacturers can drastically reduce waste.

Architecture Industry

The architecture industry is in a constant state of transformation as new technologies and methods become available. 3D printing has been called the “fourth industrial revolution,” because of its major impact on the way architects design buildings. Computer-aided design (CAD), is being used by architects, construction managers, and engineers, and has replaced manual drafting. It allows architects to create custom designs in 3D to visualize construction and enables the development, modification, and optimization of the design process, faster and more cost-effectively, without relying on costly prototyping or construction phases.

Below are some facts about 3D printing facts to help better understand its impact on modern architecture:

- 3D printing can speed up the construction process by creating customized parts quickly and cost-effectively;

- It can be used to create prototypes or test designs before starting construction, which saves time and money;

- Architects can use 3D printers to create entire building models from scratch, including details such as structural systems, windows, and doors;

- It can be used to create custom furnishings for interior spaces, such as furniture or lighting fixtures;

- 3D-printed components often require less maintenance than traditional materials or structures do, which makes them ideal for long-term use in buildings.

Conclusion

3D printing has come a long way since its beginnings. It is now being used in different industries, including healthcare, automotive, aerospace, and architecture to create inspiring prototypes and expand the possibilities of the products it prints. 3D printing has not only transformed several industries but has also saved a lot of time and resources for companies across the globe.