We’re joined today by Oscar Vail, a technology expert at the forefront of emerging fields like robotics and automation. We’ll be exploring the significant shift of humanoid robots from research labs to real-world workplaces. Our discussion will cover how these machines are addressing critical labor shortages, the technological breakthroughs making them viable, the new global supply chain that’s forming around them, and the remaining hurdles that stand in the way of widespread adoption.

We’re seeing persistent labor shortages for physically demanding roles in sectors like manufacturing and logistics. How are humanoid robots uniquely suited to fill these gaps, and what specific, real-world tasks are they currently being tested for in these environments? Please provide some detailed examples.

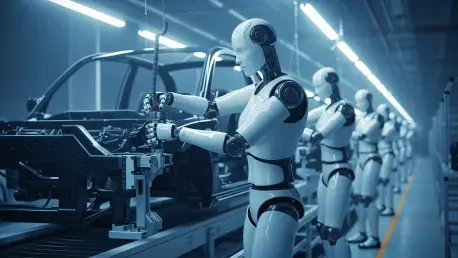

The fundamental issue isn’t just a lack of bodies, but a growing unwillingness to perform jobs that are repetitive, physically grueling, or outright hazardous. Factors like aging populations and changing career preferences have created persistent vacancies that traditional automation can’t easily fill. This is precisely where humanoid robots offer a unique solution. Unlike a fixed robotic arm, they are designed to operate in spaces built for people. They have legs to navigate narrow aisles or climb stairs and arms to reach and manipulate objects just like a human worker would. We’re seeing them being tested right now on active production lines and in busy warehouses, taking on tasks that are a direct source of physical strain for human employees.

Unlike traditional automation, humanoid robots are built to operate in spaces designed for people. What specific advantages does this offer for deployment in existing warehouses or production lines, and what recent breakthroughs in AI and motion control have finally made this practical?

The primary advantage is economic and logistical. Businesses don’t have to tear down their existing infrastructure and redesign entire facilities, which is a massive barrier to adopting older forms of automation. A humanoid robot can, in theory, be deployed into a warehouse or onto an assembly line with minimal disruption. It can switch between different workstations or tasks without major re-engineering. What has made this leap from theory to reality are recent, critical advances in AI-driven software. Specifically, perception and motion control systems have become far more sophisticated. Early models struggled with basic object recognition and spatial judgment, leading to frequent errors. Now, advanced AI allows them to navigate and react to unstructured settings, making them far more reliable and practical for the dynamic, sometimes chaotic, nature of a real workplace.

Production costs for these complex machines have reportedly dropped significantly, down to around $100,000. Could you break down the key technological factors driving this price reduction, such as in actuators and batteries, and explain how this changes the economic calculation for businesses considering adoption?

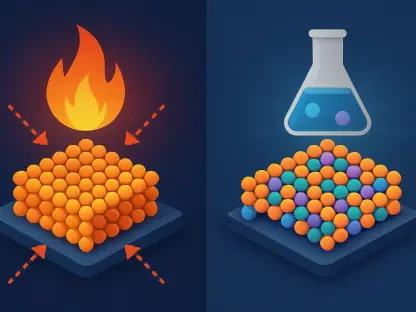

It’s a staggering transformation. Just a decade ago, a single humanoid robot was a multi-million-dollar research prototype. Now, seeing price points around $100,000 completely reframes the conversation. The cost reduction is driven by a convergence of factors. Of course, more powerful and cheaper computing hardware plays a role, but the real breakthroughs are in the physical components. We’re seeing more efficient and powerful batteries, which is essential for untethered operation. However, the most crucial advancement has been in actuators—the motors and systems that convert digital commands into physical movement. Improvements in their design and manufacturing have dramatically lowered their cost while increasing reliability. For a business, this changes everything. The robot is no longer an exotic science project but a piece of capital equipment whose return on investment can be calculated against labor costs, safety incidents, and productivity gains.

A distinct global supply chain appears to be forming, with China building robots at scale while Europe supplies critical high-precision components. Could you describe this dynamic in more detail and discuss the potential risks or benefits of this geographic specialization for future development?

It’s a fascinating and very modern supply chain dynamic. We’re observing a pattern where China is leveraging its immense manufacturing capacity to build the robots themselves at scale, handling the assembly and production in large volumes. It’s a model we’ve seen before in other tech sectors like electric vehicles. At the same time, the heart of the machine—the high-precision mechanical components that enable their advanced movement and reliability—is often coming from Europe. These are the sophisticated actuators and sensors that require specialized engineering expertise. The benefit is that this specialization accelerates progress; each region focuses on what it does best. The risk, however, is a significant supply chain dependency. Any geopolitical friction or disruption could create major bottlenecks for critical parts, potentially stalling the entire industry.

Despite recent progress, significant hurdles like energy efficiency and a lack of long-term operational data remain. Based on early trials, what are the most pressing reliability or regulatory questions that must be answered before we see widespread adoption of these robots in the workplace?

While the progress is exciting, we have to ground ourselves in the reality that this is still early days. The most pressing questions revolve around long-term reliability and safety. The industry is operating on data from early, controlled trials, not from years of robots working double shifts in a dusty warehouse. We simply don’t know how they will hold up over time. Will their energy efficiency improve to the point where they can work a full shift without constant recharging? That’s a huge operational question. On the regulatory side, we are entering uncharted territory. What are the safety standards for a fully autonomous, mobile robot working alongside people? Who is liable in an accident? These are complex legal and ethical questions that have to be answered before any company can confidently deploy these machines by the hundreds or thousands.

What is your forecast for the integration of humanoid robots into our daily work lives over the next decade?

Over the next decade, I forecast a gradual but steady integration, not a sudden takeover. We will see them become increasingly common, but they will be concentrated in specific, highly-structured environments where the tasks are undesirable for humans—think logistics centers, certain manufacturing roles, and perhaps hazardous material handling. They will function as tools, augmenting human workforces by taking on the most physically taxing and repetitive jobs, rather than replacing workers wholesale. The key will be the maturation of the technology; as reliability improves and costs continue to fall, their adoption will accelerate. But for the foreseeable future, their role will be to fill the gaps that people are already choosing to leave empty.