A significant breakthrough in materials science has been achieved by researchers at Penn State, who have successfully engineered a programmable “smart synthetic skin” with the remarkable ability to dynamically alter its appearance, texture, and physical shape on command. This innovative hydrogel-based material, created using an advanced process known as 4D printing, integrates functionalities for both adaptive camouflage and information encryption, establishing a new frontier in adaptive technologies. Unlike conventional synthetic materials, which are typically designed for a singular, specific purpose, this development introduces a single, uniform sheet of material capable of performing a multitude of complex functions simultaneously. This level of versatility, where a material can be pre-programmed to respond to environmental cues in sophisticated ways, moves us closer to a reality once confined to science fiction, where surfaces and objects can intelligently adapt to their surroundings without complex embedded electronics. The implications of such a technology are vast, promising to revolutionize fields from soft robotics to secure communications.

The Blueprint From Nature to Lab

Mimicking Nature’s Masters of Disguise

The fundamental inspiration for this sophisticated synthetic skin is drawn from the unparalleled capabilities of cephalopods, such as octopuses and squid, which are nature’s undisputed masters of disguise and communication. These marine animals possess an extraordinary biological system that allows them to instantaneously change their skin’s color, pattern, and texture, enabling them to blend seamlessly into their environment for camouflage or to display vibrant patterns for signaling other creatures. The Penn State research team sought to replicate this highly dynamic and adaptive control within a soft, synthetic framework. The objective was to translate this natural wonder into an engineered reality, achieving these complex behaviors not through intricate biological mechanisms but through the precision of digital design and advanced printing techniques. This approach effectively circumvents the need for complex, layered materials or embedded electronic components, instead encoding the desired functionalities directly into the very structure of the material itself, creating a monolithic and inherently smart substance.

A central achievement of the research is the successful integration of multiple, distinct functionalities—including adaptive camouflage, information encryption, and shape-morphing—into a single, uniform material. This monolithic design philosophy contrasts sharply with traditional engineering approaches, which often require the complex layering of different materials or the cumbersome integration of sensors, actuators, and processors to achieve similar, albeit more limited, results. By engineering a single hydrogel sheet to perform these varied tasks, the researchers have created a more robust, streamlined, and potentially scalable solution. The ability to embed complex behaviors directly into the material’s fabric represents a paradigm shift in how smart materials are conceived and manufactured. This method allows for the creation of soft, pliable systems that can adapt and respond to their environment in a holistic manner, much like their biological counterparts, opening doors to applications where lightweight, flexible, and multifunctional materials are essential for success.

The Halftone-Encoding Breakthrough

The core innovation that underpins the smart skin’s multifaceted capabilities is a novel fabrication method the researchers have termed “halftone-encoded printing.” This sophisticated technique functions by translating digital data, such as a high-resolution image or a complex texture file, into a series of meticulously arranged binary patterns. These patterns are then directly printed into the hydrogel matrix during its formation. Crucially, these embedded patterns are not merely aesthetic; they function as a localized, pre-programmed instruction set distributed throughout the material. As explained by Hongtao Sun, the project’s principal investigator and an assistant professor of industrial and manufacturing engineering at Penn State, these instructions dictate precisely how different regions of the hydrogel will react when subjected to specific environmental changes. This internal “instruction set” is the key to the material’s programmability, allowing for intricate and coordinated responses without the need for external computational control at the moment of transformation.

This pre-programmed nature is what elevates the material from a simple responsive substance to a truly “smart” skin. The halftone-encoding process allows for an immense level of control over the material’s final behavior. By modulating the density, orientation, and composition of the printed binary patterns, engineers can choreograph a wide range of transformations. For instance, a subtle gradient in the halftone pattern could translate into a smooth color change across the surface, while a more complex geometric pattern could trigger the formation of a specific 3D shape. This method essentially embeds a physical “code” within the material that is executed when the right environmental key is applied. This eliminates the need for bulky onboard power sources or processors, making the material ideal for applications where autonomy, low weight, and flexibility are paramount, such as in next-generation soft robotics or deployable structures for aerospace engineering.

Activating the Smart Skin

Programming with Stimuli

The programmable nature of this advanced smart skin is activated by a range of external environmental stimuli, allowing it to transition from a passive material to a dynamic, responsive system. Unlike static materials with fixed and unchangeable properties, this hydrogel skin is engineered to react dynamically to specific environmental triggers. These triggers can include changes in ambient temperature, the application of various solvents, or the introduction of mechanical stress like stretching or compression. When the material is exposed to one of these predefined stimuli, the embedded halftone patterns cause different areas of the hydrogel to swell, soften, or deform in highly controlled and predictable ways. This localized response, governed by the pre-printed instructions, allows for a global transformation of the material’s properties. The precision of the halftone printing ensures that these reactions are not random but follow a carefully orchestrated sequence.

By meticulously designing the initial halftone patterns, the researchers can effectively choreograph the material’s overall behavior, dictating exactly how it will transform its visual appearance, its surface texture, and its three-dimensional shape. This principle was vividly demonstrated in one of the study’s most compelling experiments, where the material was programmed to reveal hidden information. The ability to pre-determine such complex responses opens up a vast design space for creating materials with bespoke functionalities. For example, a surface could be programmed to become rougher in response to moisture to increase grip, or a soft robotic gripper could be designed to change its shape and texture to handle delicate objects when a specific chemical is detected. This level of pre-programmed control represents a significant step towards creating autonomous materials that can intelligently interact with and adapt to their surroundings.

Hiding and Revealing Information

One of the most compelling demonstrations of the smart skin’s programmability involved encoding a detailed, high-fidelity image of the Mona Lisa directly into the hydrogel material. In its baseline, inactive state, the iconic portrait was completely invisible to the naked eye. The information was effectively hidden within the material’s microstructure. When the material was washed with ethanol, a specific solvent trigger, the hydrogel became transparent, completely obscuring or “encrypting” the embedded image. However, the image could be reliably revealed, or “decrypted,” through the application of a different stimulus. By immersing the material in ice water or by gradually heating it, the programmed regions changed their optical properties in a coordinated fashion, causing the detailed portrait to become visible once again. This dynamic control over transparency and visibility showcases a powerful method for information concealment and retrieval.

This sophisticated behavior has significant potential for applications in adaptive camouflage and advanced information encryption, as highlighted by Haoqing Yang, a doctoral candidate and the study’s first author. In a military or security context, a surface coated with this material could be programmed to blend seamlessly into its environment by altering its color and pattern in response to changing light or temperature conditions. Beyond camouflage, the encryption capability offers a novel method for secure data storage. Sensitive information could be physically encoded into an object, remaining completely hidden and inaccessible until a specific, non-obvious trigger—such as a particular chemical solvent or a precise temperature sequence—is applied. This provides a form of physical cryptography where the “key” to unlock the information is an environmental condition rather than a digital password, opening new possibilities for secure communication and steganography.

More Than Meets the Eye

Mechanical Secrets and 3D Transformations

Beyond its impressive visual transformation capabilities, the smart skin can also convey hidden information through its unique mechanical properties. The research demonstrated that by gently stretching the material, the encoded patterns influence its deformation in a highly specific and non-uniform way. This subtle, programmed response to mechanical stress, which would be imperceptible in an ordinary material, can be detected and analyzed using advanced digital image correlation techniques. This process allows for the extraction of the concealed data, effectively adding another layer to its information-hiding capabilities. This moves the concept of data encryption beyond the purely visual domain and into the mechanical one, where information is stored in the material’s physical response to force. Such a feature could be used to create objects with hidden structural signatures, verifiable only through specific mechanical testing.

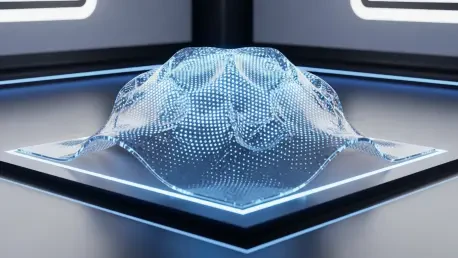

The study also showcased the hydrogel’s exceptional malleability and shape-morphing potential, a key feature of its 4D printing fabrication. The material demonstrated the ability to transform autonomously from a simple flat sheet into complex, bio-inspired three-dimensional shapes, such as a dome-like structure, without the need for multiple layers or different types of materials. In a further demonstration that integrated these functionalities, images encoded into flat films gradually became visible as the material concurrently morphed from its two-dimensional state into a three-dimensional structure. This simultaneous control over both appearance and form within a single, soft, monolithic material is a direct and powerful parallel to the coordinated control of body shape and skin patterning observed in cephalopods, highlighting the success of the bio-inspired design approach.

A Platform for Future Technologies

The development of this novel 4D printing method, utilizing a halftone-encoding strategy to create a highly programmable and multifunctional hydrogel, has established a new and scalable platform for a wide array of future technologies. The ability to embed complex “instructions” directly into the material’s structure allows for sophisticated, pre-programmed behaviors within a single substance, a feat that has historically been challenging to achieve with conventional manufacturing methods. The findings, published in the journal Nature Communications, suggest that this breakthrough could lead to the development of next-generation adaptive materials with significant implications for diverse fields. These include soft robotics, where robots could change shape and texture to navigate complex environments, and secure communication systems that rely on physical encryption.

The potential applications of this smart skin extended into advanced biomedical devices and innovative manufacturing processes. For instance, a programmable hydrogel could be used to create smart bandages that change color to indicate infection or release medicine in response to body temperature. In manufacturing, this technology could enable the creation of self-assembling structures or adaptive molds that change shape on demand. The researchers posited that their work represented a foundational step toward creating materials that are not just passive components but active, intelligent systems. This shift in material science, from static properties to programmable behaviors, had the potential to redefine how we design and build the technologies that will shape our future, enabling a new class of devices that are more integrated, responsive, and intelligent.