The prospect of generating up to one million dollars in annual savings per facility from a single technology investment is transforming how heavy industries view their digital infrastructure. For multinational cement company Cimentos de Portugal (CIMPOR), this is not a theoretical projection but a tangible goal driving the adoption of private 5G networks. In the demanding environments of cement manufacturing, where dust, vibrations, and the need for constant uptime are major challenges, a new era of connectivity is unlocking unprecedented levels of operational efficiency and financial returns. This successful deployment showcases how dedicated, high-performance wireless networks are becoming the central nervous system for modern industrial operations, enabling a suite of advanced applications that were previously impractical or impossible to implement. The initiative serves as a powerful case study for enterprises worldwide, demonstrating a clear path from technological investment to substantial, measurable business impact.

The Blueprint for Industrial Transformation

A Strategic Deployment Across Portugal

The foundation of CIMPOR’s digital evolution was laid through a strategic partnership with Ericsson and Vodafone Portugal, culminating in the successful rollout of a private 5G network across three key manufacturing plants in Alhandra, Loulé, and Souselas. These facilities, central to the company’s national operations, presented a formidable testing ground for the new technology. The network was engineered specifically for high-demand industrial settings, delivering unwavering reliability and ultra-low latency of less than 10 milliseconds. This level of performance is critical in an environment where any delay in communication can have significant safety and production consequences. Designed for resilience, the system operates seamlessly amidst the persistent dust and heavy vibrations characteristic of a cement plant, supporting a multitude of connected devices and systems simultaneously without degradation in service. The collaboration model proved highly effective, with Ericsson supplying the core radio and network equipment while Vodafone Portugal acted as the system integrator, managing the complex tasks of installation, configuration, and comprehensive service validation to ensure the network met CIMPOR’s exacting operational requirements.

Tangible Returns and Advanced Applications

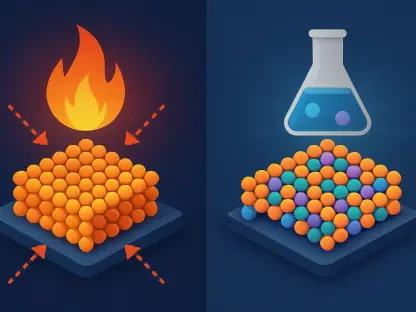

With a robust digital backbone in place, CIMPOR began leveraging the private 5G network to deploy a range of advanced industrial applications that are directly translating into operational and financial gains. The high-bandwidth, low-latency connection enables the operation of drones for inspecting kilns and other hard-to-reach or hazardous areas, drastically reducing downtime and improving worker safety. Field technicians are now equipped with smart glasses, allowing them to receive real-time remote assistance from experts located anywhere in the world, accelerating troubleshooting and repair times. Furthermore, an array of high-definition video cameras has been installed across the sites to enhance security and monitor operational processes, while a network of sensors on critical machinery facilitates sophisticated predictive maintenance. It is this last application that holds the most significant financial promise. By analyzing real-time data from equipment, CIMPOR can anticipate potential failures before they occur, preventing costly unplanned shutdowns and production disruptions. Internal assessments project that these improvements in predictive maintenance alone could generate savings of up to $1 million annually at each of the three plants.

Navigating the Competitive Landscape

The Global Ambitions of an Industry Leader

The remarkable success of the initial deployment in Portugal has solidified CIMPOR’s commitment to private 5G as a cornerstone of its global operational strategy. The company is not viewing this as a regional pilot but as a scalable blueprint for digital transformation across its entire international footprint. Plans are already underway to replicate this success across its operations in ten other countries, including major industrial markets such as Spain, Brazil, Turkey, and South Africa. This ambitious expansion reflects a strong internal consensus on the technology’s proven value and its ability to deliver a consistent return on investment in diverse industrial environments. By standardizing its connectivity infrastructure, CIMPOR aims to create a globally integrated operational model where best practices and data-driven insights can be shared seamlessly between facilities. This forward-looking approach positions the company to maintain a competitive edge in the global market, driving efficiency and innovation on a massive scale through a unified, high-performance network architecture.

A Shifting Dynamic Among Network Vendors

The CIMPOR project also highlights the evolving competitive dynamics within the private network market, particularly among its leading Western vendors. Ericsson has adopted a “gung-ho” approach, actively and aggressively pursuing opportunities in the campus-based private network sector, a strategy that appears to be paying dividends. This stands in contrast to the perceived strategy of its primary rival, Nokia, which has reportedly refined its focus to target larger, more specialized mission-critical contracts. This strategic divergence could create a significant opening for Ericsson to capture a larger share of the enterprise market. While Huawei remains the undisputed global leader in network equipment, its limited presence in many Western markets presents a unique opportunity. Currently, Nokia leads Ericsson in the Western private network space, but high-profile successes like the CIMPOR deployment could signal a potential shift in momentum. The project also clarifies the prevailing deployment model, where technology providers like Ericsson supply the foundational hardware and software, while telecommunications operators or system integrators handle the crucial on-the-ground implementation and service management.

A New Industrial Standard Was Forged

The successful implementation of private 5G across CIMPOR’s facilities did more than just enhance a single company’s operations; it established a new, validated benchmark for the entire heavy industry sector. The project moved beyond theoretical benefits and provided concrete evidence of how dedicated wireless networks could overcome long-standing industrial challenges, delivering substantial financial returns through applications like predictive maintenance and remote expert assistance. This initiative demonstrated that the technology was not only viable but also scalable, providing a clear and replicable model for multinational corporations seeking to modernize their global operations. The collaboration between a technology giant, a leading telecommunications operator, and an industrial powerhouse created a powerful synergy that ultimately forged a new standard for reliable, high-performance connectivity in the world’s most demanding environments.