The relentless march of technological progress has consistently delivered smaller, more powerful electronic devices, yet this miniaturization creates an immense engineering challenge for data storage. As components shrink, the demand for memory that can be seamlessly integrated directly onto logic circuits without consuming significant space has become critical. Ferroelectric memory has long stood out as a leading contender to meet this need, utilizing a principle of switchable electric polarization to store data in a non-volatile state. This allows information to be retained even when power is removed, a vital characteristic for the low-power operation required by everything from smartphones to the vast ecosystem of Internet-of-Things (IoT) sensors. For years, however, a significant hurdle has remained: the difficulty of aggressively downscaling these memory devices while preserving their robust performance. A recent breakthrough from a collaborative team in Japan has now directly confronted this obstacle, providing a foundational blueprint for the future of on-chip memory.

A Paradigm Shift in Miniaturization

In a significant departure from previous research efforts, which predominantly focused on thinning only the active ferroelectric layer, a team led by Professor Hiroshi Funakubo adopted a more comprehensive strategy. Their innovation was to concentrate on shrinking the entire device stack, a holistic approach that includes not just the central ferroelectric film but also the top and bottom metallic electrodes essential for the capacitor’s operation. By addressing the complete component structure, the researchers have engineered a device that is genuinely prepared for practical integration into modern semiconductor systems. The culmination of their work is a fully functional ferroelectric memory capacitor with an astonishing total thickness of just 30 nanometers. This achievement marks a new milestone in device scaling, demonstrating for the first time a viable pathway to creating memory solutions that can meet the stringent spatial constraints of next-generation electronics and logic circuits.

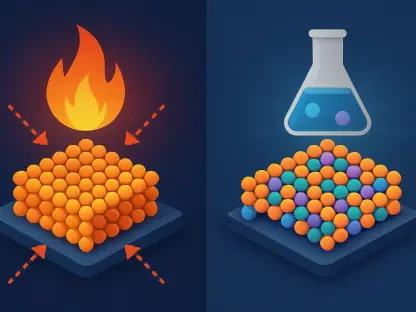

The technical design of the ultrathin capacitor underscores the novelty of this achievement, employing a three-layer sandwich structure officially designated as a Pt/(Al0.9Sc0.1)N/Pt stack. This configuration consists of a 20-nanometer-thick film of scandium-doped aluminum nitride ((Al,Sc)N), which serves as the core ferroelectric material, enclosed between two platinum (Pt) electrodes, each just 5 nanometers thick. The selection of (Al,Sc)N is particularly significant due to its strong inherent ferroelectricity, which is characterized by a high remanent polarization—the measure of polarization that persists after an external electric field is removed. This property is the physical basis for stable, non-volatile data storage. The research team successfully demonstrated that this crucial characteristic is fully maintained even at these dramatically reduced dimensions. Moreover, the inherent compatibility of (Al,Sc)N with existing semiconductor fabrication processes makes it an exceptionally strong candidate for creating unified chips that combine memory and logic.

Manufacturing Insights and Future Implications

A critical finding of the study emerged from a deep analysis of the manufacturing process, revealing that a specific post-heat treatment of the bottom platinum electrode was instrumental to the device’s success. The researchers discovered that annealing this electrode at a precise temperature of 840°C played a vital role in enhancing its crystal orientation. A well-oriented bottom electrode, in turn, acts as a superior template for the subsequent growth of the (Al,Sc)N film. This controlled growth leads to a higher-quality ferroelectric layer that exhibits vastly improved polarization switching behavior, a key factor for reliable memory operation. This insight provides an essential processing guideline for preserving high ferroelectric performance during aggressive thickness scaling, representing a key contribution that will inform the future manufacturing of such advanced memory devices and help overcome production hurdles that have previously limited progress in the field.

The implications of this research are far-reaching, as the successful demonstration of a 30-nanometer integrated capacitor stack serves as a powerful proof-of-concept for the practical realization of ultra-compact ferroelectric memory. This breakthrough is expected to inspire and accelerate the downscaling of other, more complex ferroelectric memory architectures that depend on stable polarization, including Ferroelectric Random-Access Memory (FeRAM) and Ferroelectric Tunnel Junctions (FTJ). By enabling the creation of denser memory arrays, this work paves the way for a new generation of smaller, faster, and more energy-efficient electronics across a wide spectrum of applications, from consumer gadgets to advanced industrial sensors. It effectively transitions the concept of ultrathin ferroelectric memory from a theoretical possibility, long pursued in academic labs, into a tangible and promising technological reality with a clear path toward commercial viability.

The Path Forward for On-Chip Memory

The work conducted by the Japanese research team established a new benchmark for what was possible in compact memory design. They successfully engineered a fully functional and exceptionally thin ferroelectric capacitor stack, providing a foundational technology for future on-chip memory solutions. Building on this success, the team outlined clear next steps, with a primary goal of investigating alternative electrode materials. The objective is to find materials that could promote the desired crystal orientation in the ferroelectric layer without requiring such high-temperature thermal processing. Reducing this temperature would enhance compatibility with a broader range of semiconductor manufacturing workflows, especially for back-end-of-line integration, and could also improve the device’s long-term durability. The ultimate vision was to leverage these advancements to develop the on-chip memory that would power the next generation of IoT devices, leading to more compact and efficient technologies that drive an increasingly connected world.