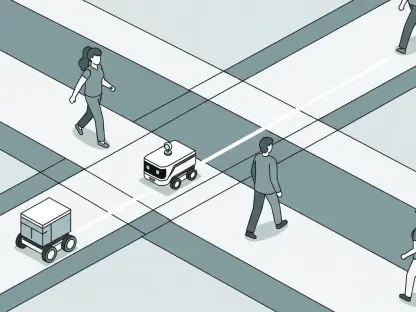

Industrial robotic automation has long been a cornerstone of manufacturing and production, but its adoption has often been limited to large enterprises with significant resources. Wandelbots, a deep tech startup, aims to change this landscape with the introduction of NOVA, the world’s first agnostic operating system for industrial robots. This groundbreaking innovation promises to make robotic automation more accessible, efficient, and scalable for businesses of all sizes.

Democratizing Access to Robotic Automation

Lowering Barriers for SMEs

Small and medium-sized enterprises (SMEs) have traditionally faced significant challenges in adopting robotic technologies. High costs, complex programming requirements, and the need for specialized expertise have often been prohibitive. NOVA aims to democratize access to industrial robotics by providing an intuitive operating system that simplifies these complexities. By lowering the barriers to entry, NOVA enables SMEs to leverage the benefits of automation without the need for extensive technical knowledge or large capital investments.

The cost factor has often been a primary hurdle for SMEs when considering automation. Robotic technology involves substantial upfront investments which can deter smaller entities. NOVA’s more affordable approach allows these businesses to implement automation solutions without overextending their budgets. Additionally, by simplifying the technical aspects, it helps overcome the learning curve associated with traditional systems, thus making robotic automation achievable for a wider range of sectors and businesses. This strategic lowering of barriers positions NOVA as a game-changer in the industrial landscape.

Intuitive User Interface

One of the standout features of NOVA is its user-friendly interface. Designed to be intuitive, the system allows employees to interact with robots easily, even if they lack in-depth technical skills. This ease of use is crucial in addressing the growing shortage of skilled robot programmers and production workers. With NOVA, businesses can train their existing workforce to operate and manage robotic systems, thereby reducing dependency on specialized personnel and fostering a more inclusive approach to automation.

The interface’s simplicity means that staff can be rapidly upskilled, mitigating the impact of the skilled labor shortage and enabling a broader group of employees to engage with robotic systems. This democratization of skill sets helps companies become more agile and adaptable, facilitating a smoother transition to automated processes. It also empowers employees who might have previously been marginalized by technological advancements, thereby opening opportunities within the workforce and driving overall productivity and efficiency in industrial environments.

Modern Programming Languages and Vendor Independence

Supporting Python and JavaScript

NOVA supports modern programming languages like Python and JavaScript, which are widely used and understood by developers across various industries. This compatibility allows developers to create and scale robotic applications with relative ease. By leveraging these popular languages, NOVA opens up new opportunities for software developers to contribute to the field of industrial automation, driving innovation and expanding the pool of available talent.

Developers benefit from the familiar syntax and paradigms of these languages, enabling faster development cycles and more robust applications. The use of widely-adopted programming languages also pushes the boundaries of what can be achieved with industrial robots, as a more extensive range of developers brings fresh perspectives and creative solutions to the table. Consequently, NOVA’s support for Python and JavaScript not only simplifies the programming process but also attracts a larger talent pool, fostering a more dynamic and innovative automation ecosystem.

Vendor-Agnostic Integration

As an agnostic operating system, NOVA integrates hardware components from various manufacturers. This vendor independence eliminates the need for businesses to rely on proprietary programming languages and closed ecosystems. By supporting a wide range of hardware, NOVA provides greater flexibility and reduces the costs associated with switching between different robotic systems. This approach not only lowers operational expenses but also allows businesses to maximize their existing investments in hardware.

This hardware-agnostic approach significantly benefits businesses by preventing vendor lock-in, allowing them to choose the best components suited to their specific needs without being tied to a single brand. This flexibility can lead to more customized and efficient automation solutions, enhancing productivity and reducing downtime associated with integrating new technologies. Furthermore, businesses can incrementally upgrade their systems as new hardware becomes available, ensuring they remain at the cutting edge of industrial automation without substantial overhauls or disruptions.

AI Integration and Strategic Partnerships

Leveraging AI Technologies

Artificial intelligence (AI) plays a central role in NOVA’s functionality. The system utilizes AI for planning, simulation, deployment, and scaling, ensuring continuous support throughout the automation lifecycle. By incorporating AI, NOVA simplifies complex processes, making it easier for businesses to implement and manage robotic automation. This integration also enhances the system’s ability to adapt to changing production needs, providing a more dynamic and responsive solution.

AI-driven capabilities in NOVA allow for real-time adjustments and decision-making, optimizing the efficiency and effectiveness of robotic operations. Businesses benefit from predictive maintenance, operational cost reductions, and enhanced throughput as the system intelligently manages robotic workflows. Furthermore, AI integration enables NOVA to learn and evolve, continuously improving its performance and adapting to new challenges. This constant evolution helps businesses stay competitive, addressing modern industrial problems and scaling their operations seamlessly.

Collaborations with Tech Giants

Wandelbots has partnered with industry leaders like Microsoft, OpenAI, and NVIDIA to enhance NOVA’s capabilities. These collaborations bring cutting-edge technologies and expertise to the platform, ensuring that NOVA remains at the forefront of innovation. By working with these tech giants, Wandelbots can leverage their resources and knowledge to continuously improve the system, offering businesses a robust and scalable solution for their automation needs.

These strategic partnerships enhance NOVA’s robustness, combining Wandelbots’ expertise in industrial robotics with the technological prowess of its collaborators, creating a synergy that pushes automation forward. Microsoft’s cloud computing capabilities, OpenAI’s expertise in artificial intelligence, and NVIDIA’s advancements in graphics processing provide NOVA with tools to deliver unparalleled performance and adaptability. As a result, NOVA becomes a comprehensive platform that not only meets current industrial demands but is also poised for future advancements, ensuring long-term value for adopters.

Cost Efficiency and Scalability

Reducing Operational Costs

One of the significant advantages of NOVA is its potential to lower the operational costs associated with automation. By allowing businesses to leverage existing hardware and scale across multiple robots and brands, NOVA reduces the need for costly new investments. This cost efficiency makes robotic automation more accessible to a broader range of businesses, including those that may have previously found it financially unfeasible.

Lowering operational costs through NOVA’s capabilities enables even financially constrained businesses to reap the benefits of automation, enhancing their competitive edge. This, in turn, facilitates broader adoption across various industries, leading to more efficient production lines and reduced waste. Moreover, the ability to scale with existing hardware investments means that companies can gradually expand their automated operations without the disruption and expense of entirely replacing their systems.

Simplifying the Automation Lifecycle

NOVA aims to simplify the entire automation lifecycle, from planning and simulation to deployment and scaling. The system’s virtual planning and simulation capabilities allow businesses to test and refine their automation strategies before committing to hardware investments. This approach reduces the risk of unnecessary expenditures and ensures that businesses can implement automation solutions that are tailored to their specific needs. By streamlining these processes, NOVA makes it easier for businesses to adopt and scale robotic automation, driving efficiency and productivity.

The simplification of the automation lifecycle supported by NOVA’s technologies means that businesses can enjoy a smoother and faster implementation process. The ability to simulate and plan in a virtual environment provides companies the opportunity to identify and address potential issues before they become costly problems in real-world settings. This foresight and planning reduce the likelihood of production downtime and rework, resulting in more efficient operations and quicker returns on automation investments.

Addressing the Skilled Labor Shortage

Unified User Interface

The shortage of skilled labor in the field of industrial automation is a growing concern. NOVA addresses this issue by offering a unified user interface that simplifies the interaction between humans and robots. This ease of use allows businesses to train their existing workforce to operate and manage robotic systems, reducing dependency on specialized personnel. By making automation more accessible to a broader range of employees, NOVA helps businesses overcome the challenges posed by the skilled labor shortage.

The unified user interface designed by NOVA is a critical component in bridging the gap caused by the scarcity of skilled labor. Employees who might not have engineering degrees or advanced training can be efficiently educated to utilize and manage robotic systems. This inclusivity ensures a broader range of employees get involved in automation processes, increasing job satisfaction and reducing turnover. By addressing the skilled labor shortage in this way, NOVA ensures businesses maintain operational efficiency and competitiveness despite workforce limitations.

Opportunities for Software Developers

Industrial robotic automation has traditionally served as a critical component in manufacturing and production sectors. However, its widespread adoption has often been constrained to large enterprises equipped with substantial resources, leaving smaller businesses unable to harness its potential. Wandelbots, an innovative deep tech startup, seeks to revolutionize this scenario through the launch of NOVA, acclaimed as the world’s first agnostic operating system designed for industrial robots. This pioneering development aims to democratize robotic automation, making it more accessible, efficient, and scalable for enterprises of all sizes.

With NOVA, Wandelbots aspires to bridge the gap between large corporations and smaller businesses by providing an adaptable and user-friendly solution for incorporating robotic technology. The introduction of NOVA is set to transform how businesses approach automation, enabling even those with limited resources to benefit from increased productivity and operational efficiency. By leveling the playing field, Wandelbots is poised to usher in a new era of inclusive technological advancement in the industrial sector.